J Adv Prosthodont.

2010 Dec;2(4):117-121. 10.4047/jap.2010.2.4.117.

Effect of soldering techniques and gap distance on tensile strength of soldered Ni-Cr alloy joint

- Affiliations

-

- 1Department of Prosthodontics, College of Dentistry, Dankook University, Cheonan, Korea. hyuk928@chol.com

- KMID: 1975185

- DOI: http://doi.org/10.4047/jap.2010.2.4.117

Abstract

- PURPOSE

The present study was intended to evaluate the effect of soldering techniques with infrared ray and gas torch under different gap distances (0.3 mm and 0.5 mm) on the tensile strength and surface porosity formation in Ni-Cr base metal alloy.

MATERIALS AND METHODS

Thirty five dumbbell shaped Ni-Cr alloy specimens were prepared and assigned to 5 groups according to the soldering method and the gap distance. For the soldering methods, gas torch (G group) and infrared ray (IR group) were compared and each group was subdivided by corresponding gap distance (0.3 mm: G3 and IR3, 0.5 mm: G5, IR5). Specimens of the experimental groups were sectioned in the middle with a diamond disk and embedded in solder blocks according to the predetermined distance. As a control group, 7 specimens were prepared without sectioning or soldering. After the soldering procedure, a tensile strength test was performed using universal testing machine at a crosshead speed 1 mm/min. The proportions of porosity on the fractured surface were calculated on the images acquired through the scanning electronic microscope.

RESULTS

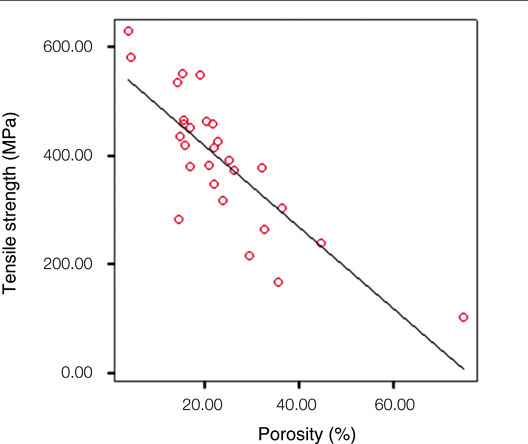

Every specimen of G3, G5, IR3 and IR5 was fractured on the solder joint area. However, there was no significant difference between the test groups (P > .05). There was a negative correlation between porosity formation and tensile strength in all the specimens in the test groups (P < .05).

CONCLUSION

There was no significant difference in ultimate tensile strength of joints and porosity formations between the gas-oxygen torch soldering and infrared ray soldering technique or between the gap distance of 0.3 mm and 0.5 mm.

Keyword

MeSH Terms

Figure

Cited by 1 articles

-

Study on the effect of soldering methods on the characteristics of the Ni-Cr alloy

Chul-Hyung Kim, Young-Gyun Song, Jong-Hyuk Lee

J Korean Acad Prosthodont. 2012;50(1):53-60. doi: 10.4047/jkap.2012.50.1.53.

Reference

-

1. Blustein R, DePaul BM, Barnhart RC Jr, Green KA. A reliable technique of post soldering of nonprecious ceramic units. J Prosthet Dent. 1976. 36:112–114.2. Huget EF, Vlica JM, Wall RM. Characterization of two ceramic-base-metal alloys. J Prosthet Dent. 1978. 40:637–641.3. Moffa JP, Lugassy AA, Guckes AD, Gettleman L. An evaluation of nonprecious alloys for use with porcelain veneers. Part I. Physical properties. J Prosthet Dent. 1973. 30:424–431.4. Nikellis I, Levi A, Zinelis S. Effect of soldering on the metal-ceramic bond strength of an Ni-Cr base alloy. J Prosthet Dent. 2005. 94:435–439.5. Shillingburg HT, Hobo S, Whitsett LD, Jacobi R, Brackett SE. Fundamentals of Fixed Prosthodontics. 1997. 3rd ed. Chicago: Quintessence Publishing;509.6. Anwar EM, Naggar GA. Effect of different gap distances on the tensile strength and microstructure of infra-red soldered joints. Cairo Dent J. 2004. 20:149–155.7. Marshall AG, Goodkind RJ. An investigation of the tensile strength of nickel-chromium alloy dental solder joints. J Prosthet Dent. 1984. 52:666–672.8. Rasmussen EJ, Goodkind RJ, Gerberich WW. An investigation of tensile strength of dental solder joints. J Prosthet Dent. 1979. 41:418–423.9. Watanabe I, Watanabe E, Atsuta M, Okabe T. Tensile strength of soldered gold alloy joints. J Prosthet Dent. 1997. 78:260–266.10. el-Ebrashi MK, Craig RG, Peyton FA. Experimental stress analysis of dental restorations. VII. Structural design and stress analysis of fixed partial dentures. J Prosthet Dent. 1970. 23:177–186.11. Kaylakie WG, Brukl CE. Comparative tensile strengths of nonnoble dental alloy solders. J Prosthet Dent. 1985. 53:455–462.12. Anusavice KJ, Okabe T, Galloway SE, Hoyt DJ, Morse PK. Flexure test evaluation of presoldered base metal alloys. J Prosthet Dent. 1985. 54:507–517.13. Townsend LW, Vermilyea SG, Griswold WH. Soldering nonnoble alloys. J Prosthet Dent. 1983. 50:51–53.14. Stackhouse JA Jr. Assembly of dental units by soldering. J Prosthet Dent. 1967. 18:131–139.15. Stade EH, Reisbick MH, Preston JD. Preceramic and postceramic solder joints. J Prosthet Dent. 1975. 34:527–532.16. Willis LM, Nicholls JI. Distortion in dental soldering as affected by gap distance. J Prosthet Dent. 1980. 43:272–278.17. Ryge G, Kozak SF, Fairhurst CW. Porosities in dental gold castings. J Am Dent Assoc. 1957. 54:746–754.18. Carlberg T, Wictorin L. Soldering of dental alloys under vacuum by IR-heating. Dent Mater. 1986. 2:279–283.19. Tehini GE, Stein RS. Comparative analysis of two techniques for soldered connectors. J Prosthet Dent. 1993. 69:16–19.20. Cattaneo G, Wagnild G, Marshall G, Watanabe L. Comparison of tensile strength of solder joints by infrared and conventional torch technique. J Prosthet Dent. 1992. 68:33–37.21. Chaves M, Vermilyea SG, Papazoglou E, Brantley WA. Effects of three soldering techniques on the strength of high-palladium alloy solder joints. J Prosthet Dent. 1998. 79:677–684.22. Cheng AC, Chai JY, Gilbert J, Jameson LM. Mechanical properties of metal connectors soldered by gas torch versus an infrared technique. J Prosthodont. 1993. 2:103–109.23. Ryge G. Dental soldering procedures. Dent Clin North Am. 1958. 2:747–757.24. Anusavice KJ, Shafagh I. Inert gas presoldering of nickel-chromium alloys. J Prosthet Dent. 1986. 55:317–323.25. Nicholls JI, Lemm RW. Tensile strength of presoldered and postsoldered joints. J Prosthet Dent. 1985. 53:476–482.26. Sobieralski JA, Brukl CE, Smith NK. Tensile strengths and microscopic analysis of nickel-chromium base metal postceramic solder joints. J Prosthet Dent. 1987. 58:35–42.27. Cheng AC, Chai JY, Gilbert J, Jameson LM. Investigation of stiffness and microstructure of joints soldered with gas-oxygen torch and infrared methods. J Prosthet Dent. 1994. 72:8–15.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Study on the effect of soldering methods on the characteristics of the Ni-Cr alloy

- A MEASUREMENT OF DISPLACEMENTS OF CAST FRAMEWORK BY TORCH SOLDERING AND ELECTRIC SOLDERING TECHNIQUES

- The study of tension characteristics in orthodontic wires

- EFFECTOF SOLDERING CONDITION ON THE TENSILE STRENGTH TITANIUM SOLDER JOINT WITH 14K GOLD SOLDER

- The Effects Of Thermocycling On The Bond Strength Between Cobalt-Chromium Alloy And Denture Base Resin