J Adv Prosthodont.

2014 Aug;6(4):272-277. 10.4047/jap.2014.6.4.272.

Evaluation of shear bond strength of repair acrylic resin to Co-Cr alloy

- Affiliations

-

- 1Department of Prosthodontics, Faculty of Dentistry, 19 Mayis University, Samsun, Turkey.

- 2Department of Prosthodontic, Faculty of Dentistry, Bulent Ecevit University, Zonguldak, Turkey. sedabc@hotmail.com

- KMID: 1974846

- DOI: http://doi.org/10.4047/jap.2014.6.4.272

Abstract

- PURPOSE

The purpose of this study was to investigate the impact of different surface treatment methods and thermal ageing on the bond strength of autopolymerizing acrylic resin to Co-Cr.

MATERIALS AND METHODS

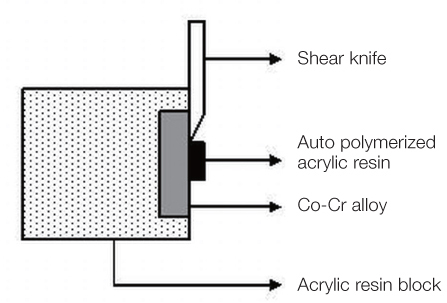

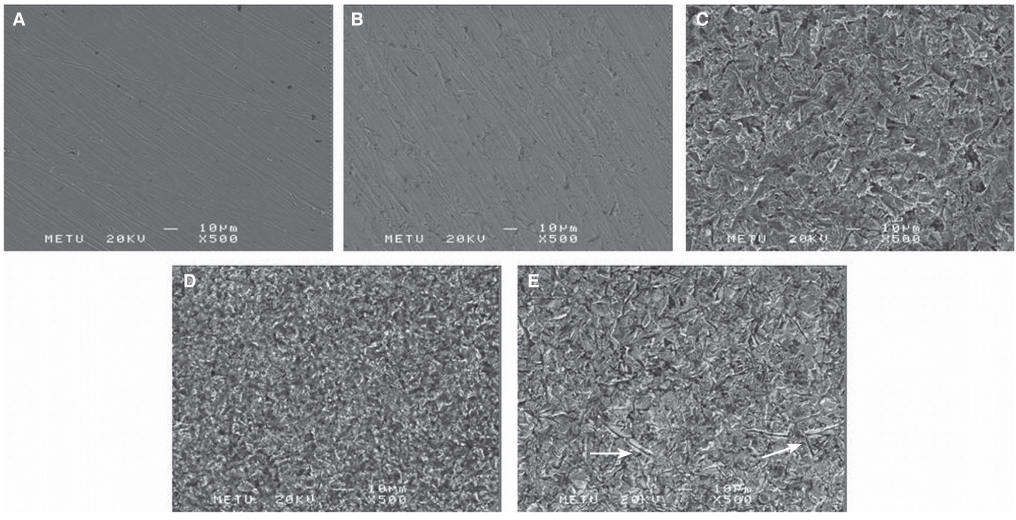

Co-Cr alloy specimens were divided into five groups according to the surface conditioning methods. C: No treatment; SP: flamed with the Silano-Pen device; K: airborne particle abrasion with Al2O3; Co: airborne particle abrasion with silica-coated Al2O3; KSP: flamed with the Silano-Pen device after the group K experimental protocol. Then, autopolymerized acrylic resin was applied to the treated specimen surfaces. All the groups were divided into two subgroups with the thermal cycle and water storage to determine the durability of the bond. The bond strength test was applied in an universal test machine and treated Co-Cr alloys were analyzed by scanning electron microscope (SEM). Two-way analysis of variance (ANOVA) was used to determine the significant differences among surface treatments and thermocycling. Their interactons were followed by a multiple comparison' test performed uing a post hoc Tukey HSD test (alpha=0.05).

RESULTS

Surface treatments significantly increased repair strengths of repair resin to Co-Cr alloy. The repair strengths of Group K, and Co significantly decreased after 6,000 cycles (P<.001).

CONCLUSION

Thermocycling lead to a significant decrease in shear bond strength for air abrasion with silica-coated aluminum oxide particles. On the contrary, flaming with Silano-Pen did not cause a significant reduction in adhesion after thermocycling.

Keyword

Figure

Reference

-

1. Ohkubo C, Watanabe I, Hosoi T, Okabe T. Shear bond strengths of polymethyl methacrylate to cast titanium and cobalt-chromium frameworks using five metal primers. J Prosthet Dent. 2000; 83:50–57.2. Bulbul M, Kesim B. The effect of primers on shear bond strength of acrylic resins to different types of metals. J Prosthet Dent. 2010; 103:303–308.3. Kim JY, Pfeiffer P, Niedermeier W. Effect of laboratory procedures and thermocycling on the shear bond strength of resin-metal bonding systems. J Prosthet Dent. 2003; 90:184–189.4. Maruo Y, Nishigawa G, Oka M, Minagi S, Suzuki K, Irie M. Does plasma irradiation improve shear bond strength of acrylic resin to cobalt-chromium alloy? Dent Mater. 2004; 20:509–512.5. Shimizu H, Kurtz KS, Tachii Y, Takahashi Y. Use of metal conditioners to improve bond strengths of autopolymerizing denture base resin to cast Ti-6Al-7Nb and Co-Cr. J Dent. 2006; 34:117–122.6. Banerjee S, Engelmeier RL, O'Keefe KL, Powers JM. In vitro tensile bond strength of denture repair acrylic resins to primed base metal alloys using two different processing techniques. J Prosthodont. 2009; 18:676–683.7. Pesun S, Mazurat RD. Bond strength of acrylic resin to cobalt-chromium alloy treated with the Silicoater MD and Kevloc systems. J Can Dent Assoc. 1998; 64:798–802.8. Mudford L, Curtis RV, Walter JD. An investigation of debonding between heat-cured PMMA and titanium alloy (Ti-6A1-4V). J Dent. 1997; 25:415–421.9. NaBadalung DP, Powers JM, Connelly ME. Comparison of bond strengths of denture base resins to nickel-chromium-beryllium removable partial denture alloy. J Prosthet Dent. 1997; 78:566–573.10. Sharp B, Morton D, Clark AE. Effectiveness of metal surface treatments in controlling microleakage of the acrylic resin-metal framework interface. J Prosthet Dent. 2000; 84:617–622.11. Sanohkan S, Urapepon S, Harnirattisai C, Sirisinha C, Sunintaboon P. Shear bond strength between autopolymerizing acrylic resin and Co-Cr alloy using different primers. Dent Mater J. 2012; 31:765–771.12. Rached RN, Powers JM, Del Bel Cury AA. Repair strength of autopolymerizing, microwave, and conventional heat-polymerized acrylic resins. J Prosthet Dent. 2004; 92:79–82.13. Nagai E, Otani K, Satoh Y, Suzuki S. Repair of denture base resin using woven metal and glass fiber: effect of methylene chloride pretreatment. J Prosthet Dent. 2001; 85:496–500.14. Leibrock A, Degenhart M, Behr M, Rosentritt M, Handel G. In vitro study of the effect of thermo- and load-cycling on the bond strength of porcelain repair systems. J Oral Rehabil. 1999; 26:130–137.15. Ishii T, Koizumi H, Tanoue N, Naito K, Yamashita M, Matsumura H. Effect of alumina air-abrasion on mechanical bonding between an acrylic resin and casting alloys. J Oral Sci. 2009; 51:161–166.16. Janda R, Roulet JF, Latta M, Damerau G. Spark erosion as a metal-resin bonding system. Dent Mater. 2007; 23:193–197.17. Matinlinna JP, Vallittu PK. Silane based concepts on bonding resin composite to metals. J Contemp Dent Pract. 2007; 8:1–8.18. Clelland NL, van Putten MC, Brantley WA, Knobloch LA. Adhesion testing of a denture base resin with 5 casting alloys. J Prosthodont. 2000; 9:30–36.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- The Effects Of Thermocycling On The Bond Strength Between Cobalt-Chromium Alloy And Denture Base Resin

- THE EFFECTS OF THERMAL CYCLING ON THE BOND STRENGTH OF SELF-CURING RESIN

- Effect of metal primers and tarnish treatment on bonding between dental alloys and veneer resin

- THE EFFECTS OF METAL SURFACE TREATMENTS ON THE BONE STRENGTH OF POLYMETHYL METHACRYLATE BONDED REMOVABLE PROSTHESE

- The effect of Zirconium Nitride coating on shear bond strength with denture base resin in Co-Cr alloy and titanium alloy