J Korean Hip Soc.

2010 Sep;22(3):227-233. 10.5371/jkhs.2010.22.3.227.

The Tribological and Lubrication Responses of a Cobalt-Chromium Femoral Head in Total Hip Arthroplasty

- Affiliations

-

- 1Institute for Skeletal Aging & Department of Orthopedic Surgery, College of Medicine, Hallym University, Chuncheon, Korea. totalhip@hallym.ac.kr

- 2School of Mechanical Engineering, Pusan National University, Busan, Korea.

- KMID: 1461175

- DOI: http://doi.org/10.5371/jkhs.2010.22.3.227

Abstract

- PURPOSE

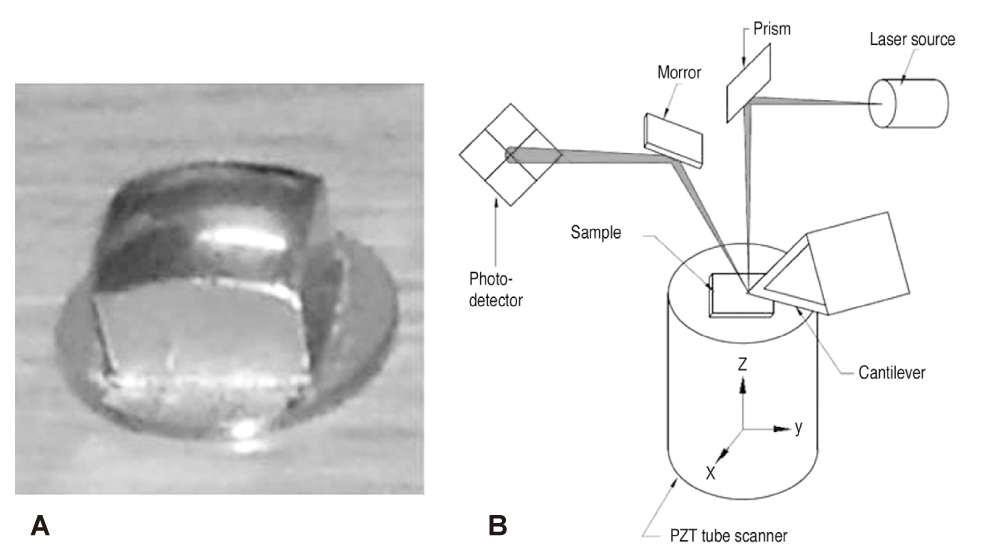

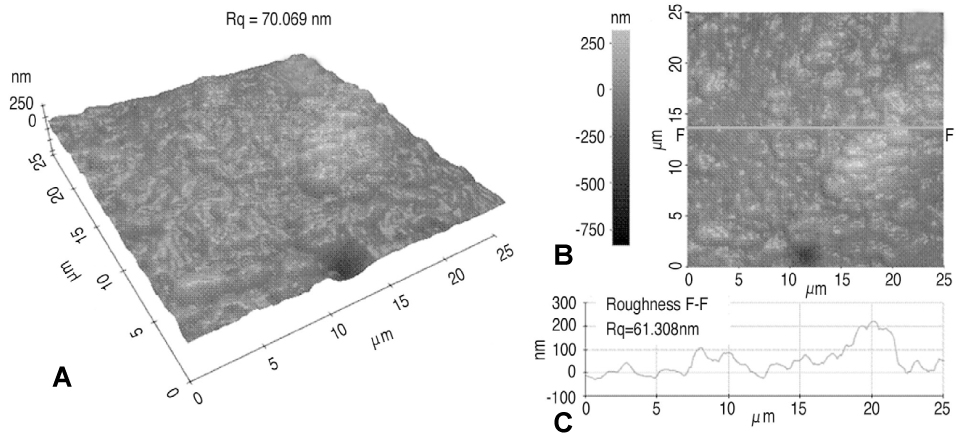

This study aimed at investigating the role of albumin as a boundary lubricant in the lubrication of the Co-Cr femoral head of artificial hip implants by measuring the tribological parameters of the Co-Cr femoral head with Atomic Force Microscope (AFM) techniques.

MATERIALS AND METHODS

Samples were prepared from the main wear region of a Co-Cr femoral head from revision hip surgery. Two types of solutions were prepared as lubricants: PBS (Phosphate Buffered Saline) as a control solution and BSA (Bovine Serum Albumin) as a lubricant at concentrations of 10, 20, 30 and 40 mg/ml in PBS solution.

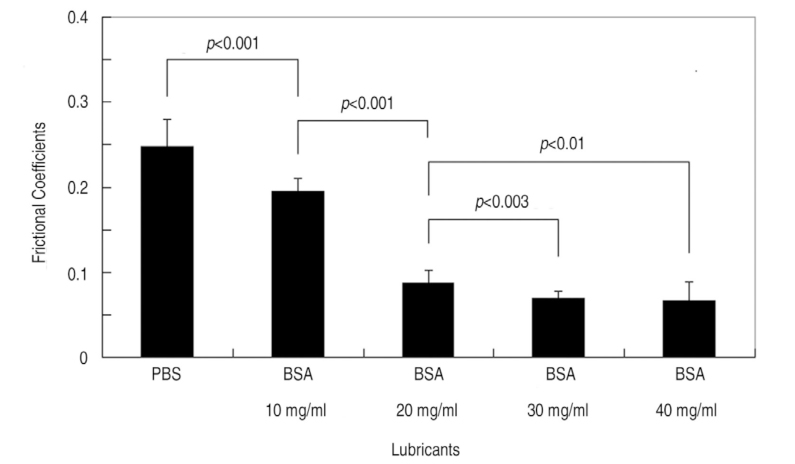

RESULTS

There were statistically significant differences in the frictional coefficients (micron) of a Co-Cr head between the PBS control and all the concentrations of BSA (10, 20, 30, 40 mg/ml) (P<0.001). Similarly, there were statistically significant differences for the micron between the BSA concentrations of 10, 20, 30 and 40 mg/m for all the cases except between the BSA of 30 and 40 mg/ml (P<0.01).

CONCLUSION

There exists a maximum protein concentration of BSA to play a role as an effective boundary lubricant through adsorption on the surface of Co-Cr femoral head.

Keyword

Figure

Reference

-

1. Brockett C, Williams S, Jin Z, Isaac G, Fisher J. Friction of total hip replacements with different bearings and loading conditions. J Biomed Mater Res B Appl Biomater. 2007. 81:508–515.

Article2. Sedel L. Evolution of alumina-on-alumina implants: a review. Clin Orthop Relat Res. 2000. 379:48–54.3. Bhushan B. Nanotribology, nanomechanics and nanomaterials characterization. Philos Transact A Math Phys Eng Sci. 2008. 366:1351–1381.

Article4. Park S, Costa KD, Ateshian GA. Microscale frictional response of bovine articular cartilage from atomic force microscopy. J Biomech. 2004. 37:1679–1687.

Article5. Gispert MP, Serro AP, Colaço R, Saramago B. Friction and wear mechanisms in hip prosthesis: Comparison of joint materials behaviour in several lubricants. Wear. 2006. 260:149–158.

Article6. Scholes SC, Unsworth A, Hall RM, Scott R. The effects of material combination and lubricant on the friction of total hip prostheses. Wear. 2000. 241:209–213.

Article7. Cho HJ, Wei WJ, Kao HC, Cheng CK. Wear behavior of UHMWPE sliding on artificial hip arthroplasty materials. Mater Chem Phys. 2004. 88:9–16.

Article8. Saikko V. Friction measurement in the biaxial rocking motion hip joint simulator. J Tribol. 2009. 131:011201.

Article9. Wang FC, Brockett C, Williams S, Udofia I, Fisher J, Jin ZM. Lubrication and friction prediction in metal-on-metal hip implants. Phys Med Biol. 2008. 53:1277–1293.

Article10. Duong CT, Nam JS, Seo EM, et al. Tribological property of the cobalt-chromium femoral head with different regions of wear in total hip arthroplasty. Proc Inst Mech Eng H. 2010. 224:541–549.

Article11. Arias DF, Marulanda DM, Baena AM, Devia A. Determination of friction coefficient on ZrN and TiN using lateral force microscopy (LFM). Wear. 2006. 261:1232–1236.

Article12. Smith AM, Chapman CE, Deslandes M, Langlais JS, Thibodeau MP. Role of friction and tangential force variation in the subjective scaling of tactile roughness. Exp Brain Res. 2002. 144:211–223.

Article13. Jiang H, Browning R, Fincher J, Gasbarro A, Jones S, Sue HJ. Influence of surface roughness and contact load on friction coefficient and scratch behavior of thermoplastic olefins. Appl Surf Sci. 2008. 254:4494–4499.

Article14. Menezes PL, Kishore , Kailas SV. Influence of roughness parameters on coefficient of friction under lubricated conditions. Sadhana. 2008. 33:181–190.

Article15. Menezes PL, Kishore , Kailas SV. On the effect of surface texture on friction and transfer layer formation-A study using Al and steel pair. Wear. 2008. 265:1655–1669.

Article16. Sedlacek M, Podgornik B, Vizintin J. Influence of surface preparation on roughness parameters, friction and wear. Wear. 2009. 266:482–487.

Article17. Hwang DS, Kim YM, Lee CH. Alumina femoral head fracture in uncemented total hip arthroplasty with a ceramic sandwich cup. J Arthroplasty. 2007. 22:468–471.

Article18. Teoh SH, Chan WH, Thampuran R. An elasto-plastic finite element model for polyethylene wear in total hip arthroplasty. J Biomech. 2002. 35:323–330.

Article19. Brown SS, Clarke IC. A review of lubricant conditions for wear simulation in artificial hip joint replacements. Tribol Trans. 2006. 49:72–78.

Article20. Saikko V. Effect of lubricant protein concentration on the wear of ultra-high molecular weight polyethylene sliding against a CoCr counterface. J Tribol. 2003. 125:638–642.

Article21. Clarke IC, Chan FW, Essner A, et al. Multi-laboratory simulator studies on effects of serum proteins on PTFE cup wear. Wear. 2001. 250:188–198.

Article22. Wang A, Essner A, Schmidig G. The effects of lubricant composition on in vitro wear testing of polymeric acetabular components. J Biomed Mater Res B Appl Biomater. 2004. 68:45–52.23. O'Connor DT, Choi MG, Kwon SY, Paul Sung KL. New insight into the mechanism of hip prosthesis loosening: effect of titanium debris size on osteoblast function. J Orthop Res. 2004. 22:229–236.24. Heuberger MP, Widmer MR, Zobeley E, Glockshuber R, Spencer ND. Protein-mediated boundary lubrication in arthroplasty. Biomaterials. 2005. 26:1165–1173.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Metal Ion Release after a Metal-on-Metal Hip Arthroplasty: Comparison between Resurfacing Arthroplasty and Total Hip Arthroplasty

- Granulomatous Lung Disease: A Novel Complication following Metallosis from Hip Arthroplasty

- Periprosthetic Femoral Fractures after Hip Arthroplasty

- Sensory Polyneuropathy and Cobalt Intoxication after Metal-on-Metal Total Hip Arthroplasty

- Total Hip Arthroplasty Using a Large Femoral Head: The Short-Term Follow-up Results and the Early Complications