Korean J Orthod.

2023 Mar;53(2):89-98. 10.4041/kjod22.183.

Thermo-mechanical properties in bending of a multizone nickel-titanium archwire: A retrieval analysis

- Affiliations

-

- 1Department of Orthodontics, School of Dentistry, National and Kapodistrian University of Athens, Athens, Greece

- 2Department of Oral Technology, School of Dentistry, University Hospital Bonn, Bonn, Germany

- 3Clinic of Orthodontics and Paediatric Dentistry, Center of Dental Medicine, University of Zurich, Zurich, Switzerland

- KMID: 2540948

- DOI: http://doi.org/10.4041/kjod22.183

Abstract

Objective

This study aimed to compare the mechanical and thermal properties in the anterior and posterior segments of new and retrieved specimens of a commercially available multizone superelastic nickel-titanium (NiTi) archwire.

Methods

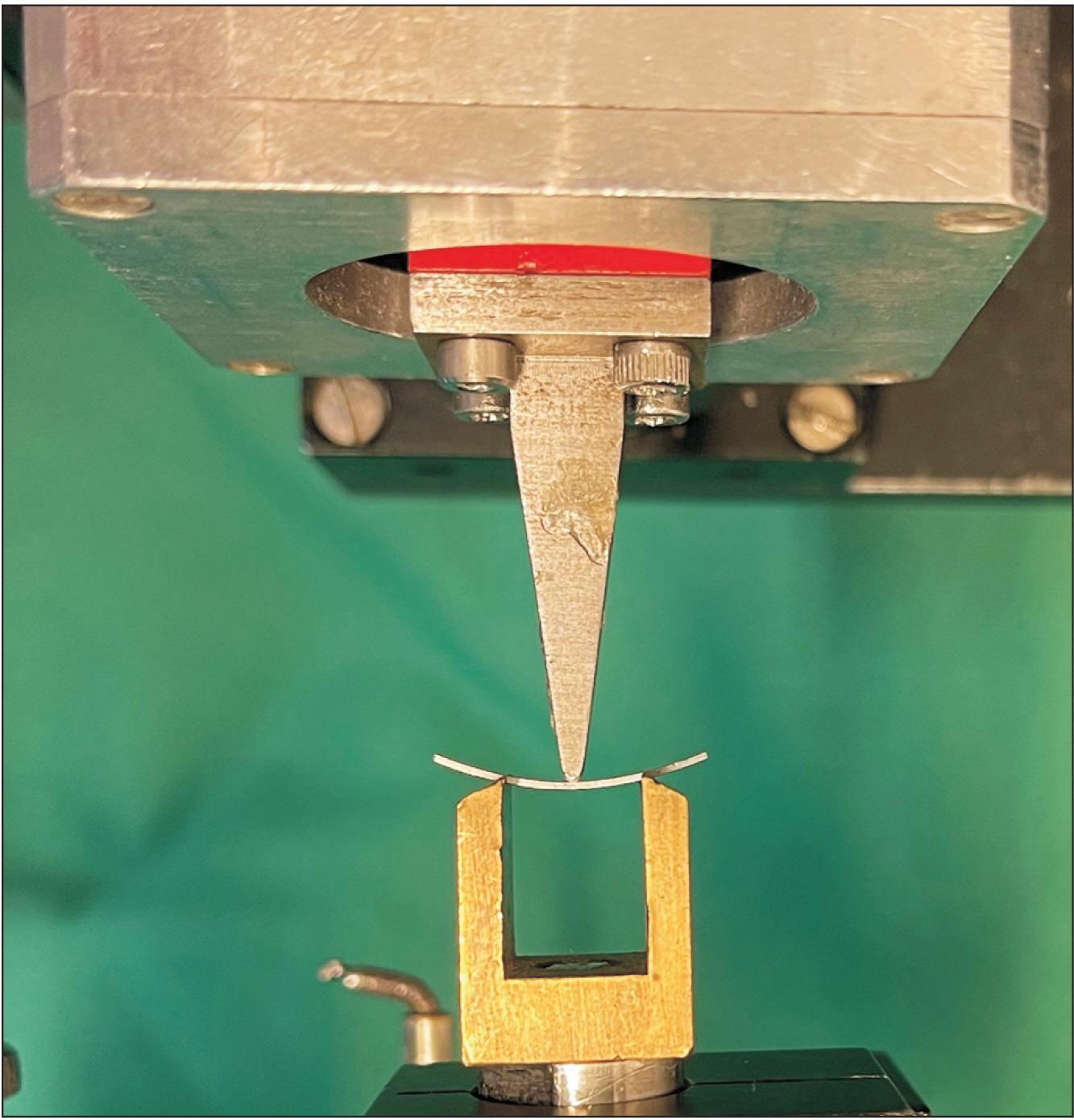

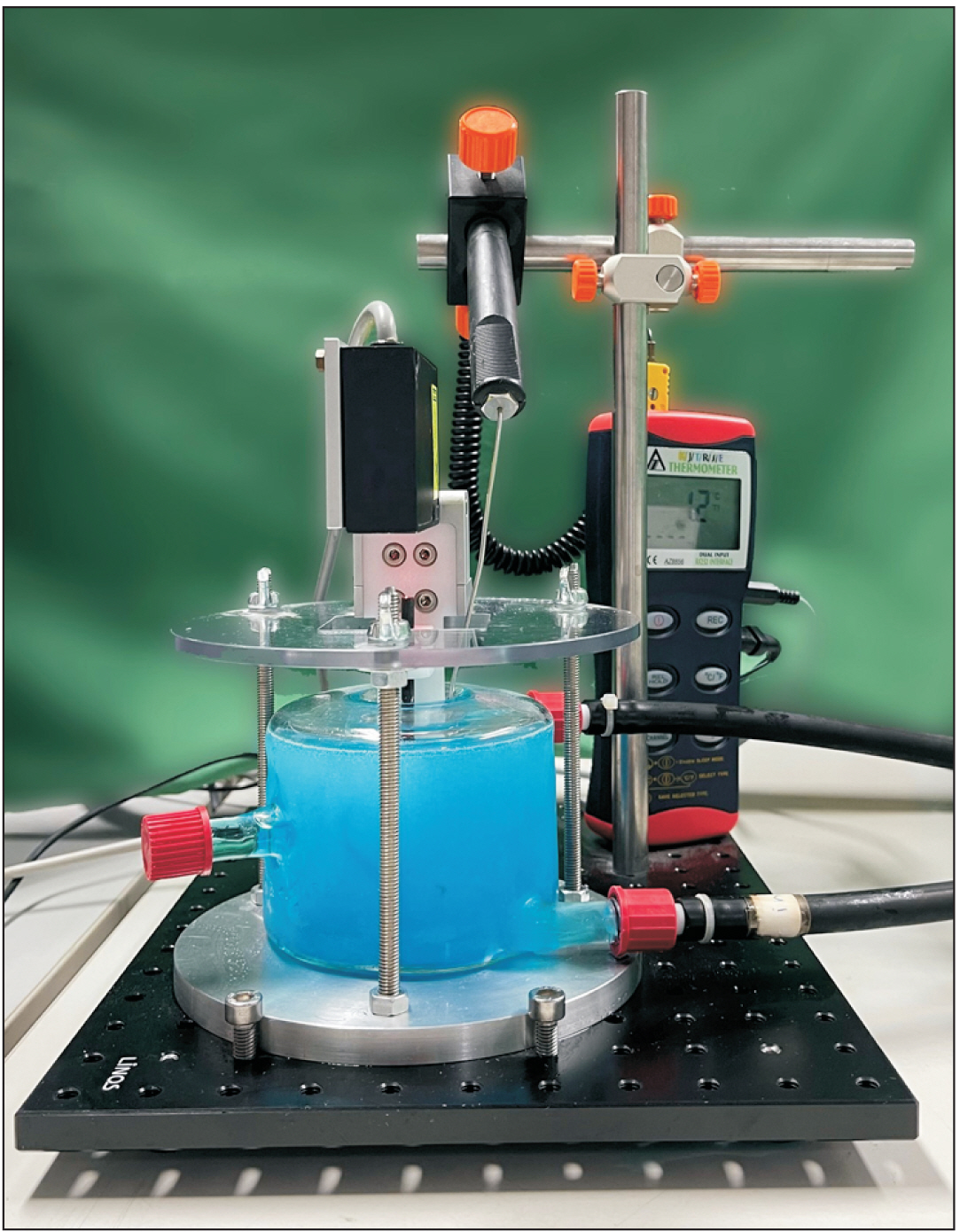

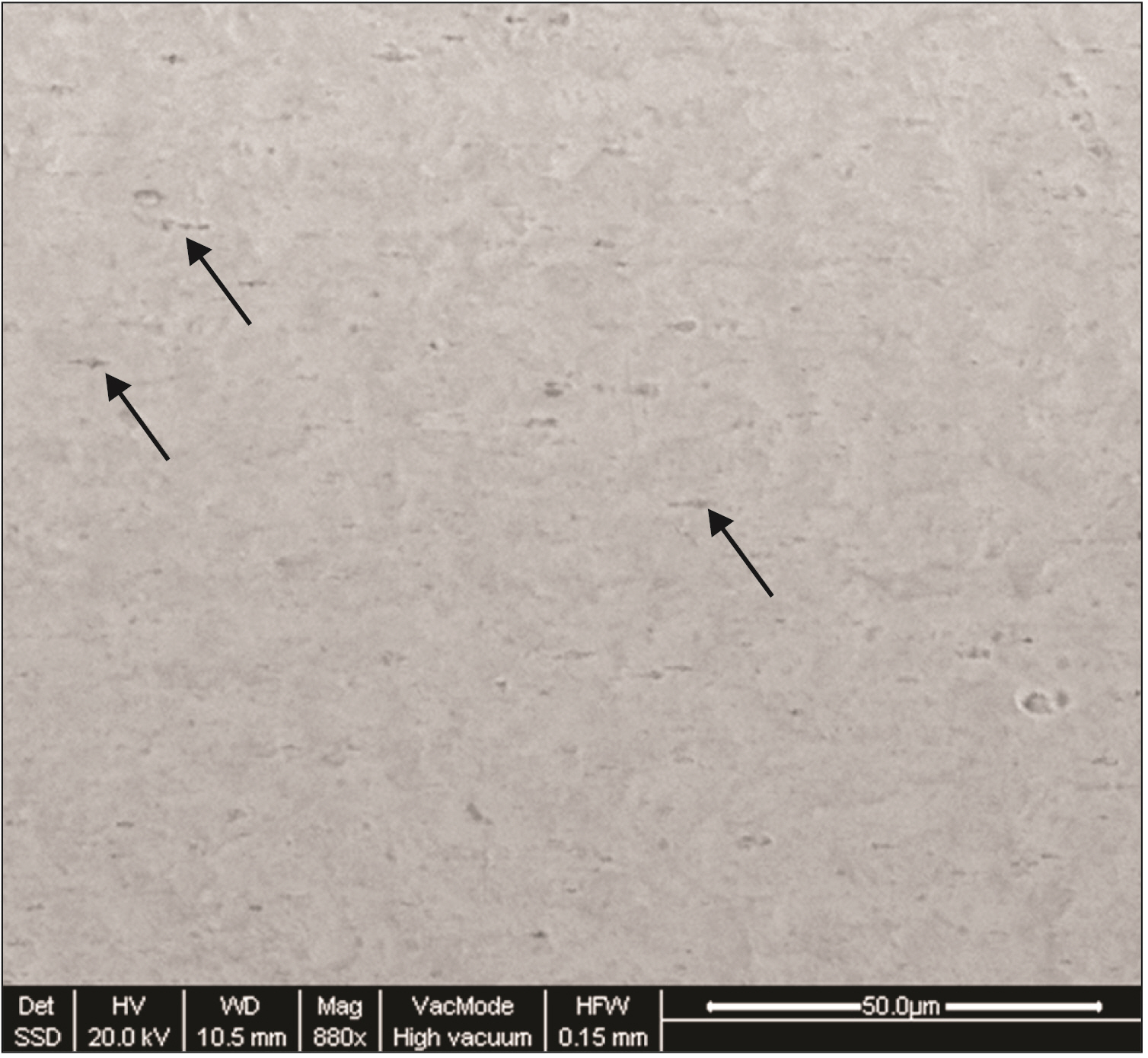

The following groups of 0.016 × 0.022-inch Bioforce NiTi archwires were compared: a) anterior and b) posterior segments of new specimens and c) anterior and d) posterior segments of retrieved specimens. Six specimens were evaluated in each group, by three-point bending and bend and free recovery tests. Bending moduli (Eb) were calculated. Furthermore, the new specimens were evaluated with scanning electron microscopy/energy-dispersive X-ray spectrometry. A multiple linear regression model with a random intercept at the wire level was applied for data analysis.

Results

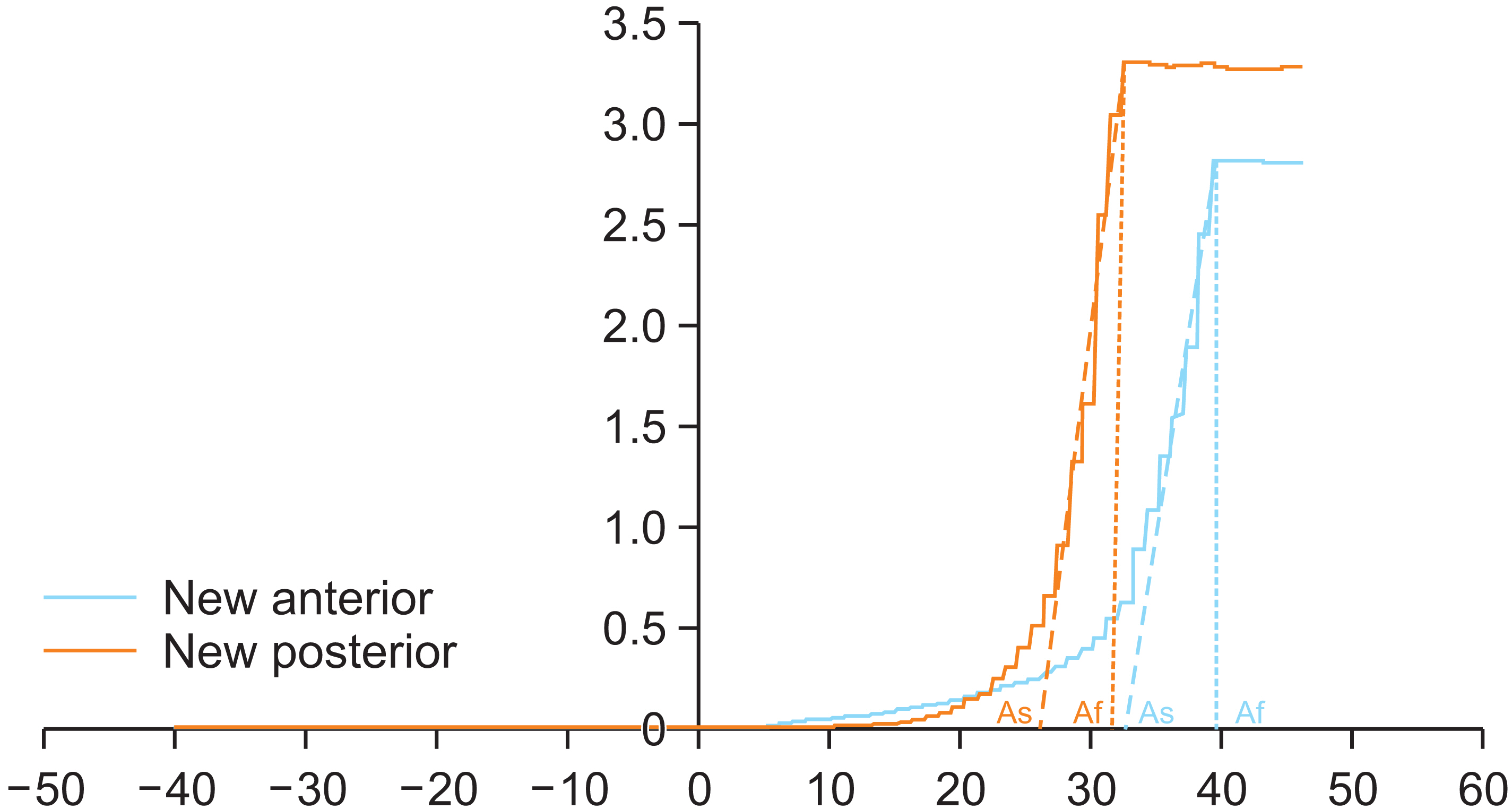

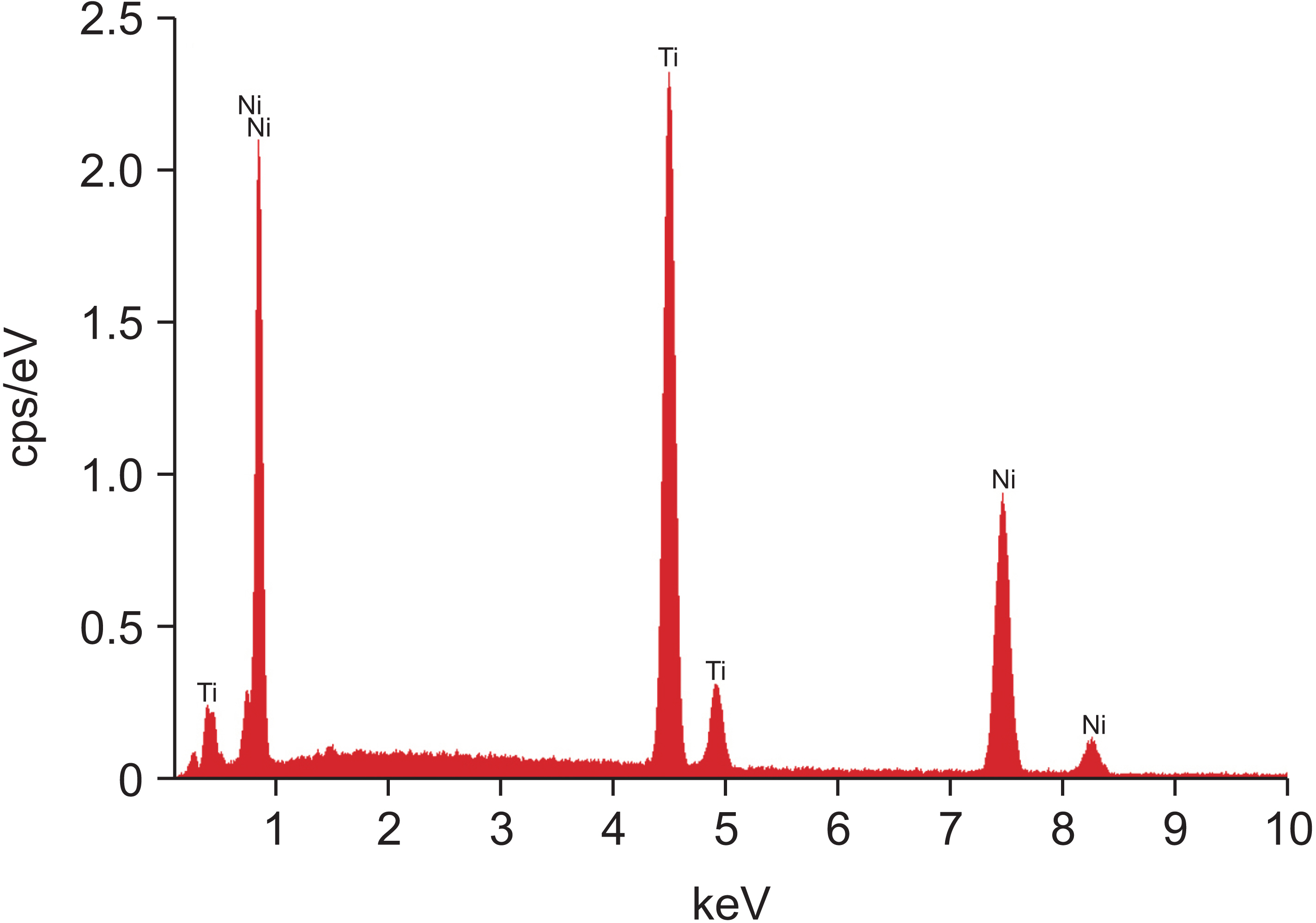

The forces in the posterior segments or new specimens were higher than those recorded in the anterior segments or retrieved specimens, respectively. Accordingly, Eb also varied. Higher austenite start and austenite finish (Af) temperatures were recorded in the anterior segments. No statistically significant differences were found for these temperatures between retrieved and new wires. The mean elemental composition was (weight percentage): Ni, 52.6 ± 0.5; Ti, 47.4 ± 0.5.

Conclusions

The existence of multiple force zones was confirmed in new and retrieved Bioforce archwires. The retrieved archwires demonstrated lower forces during the initial stages of deactivation in three-point bending tests, compared with new specimens. The Af temperature of these archwires may lie higher than the regular intraoral temperature. Even at 2 mm deflections, the forces recorded from these archwires may lie beyond biologically safe limits.

Figure

Reference

-

1. Miura F, Mogi M, Ohura Y, Hamanaka H. 1986; The super-elastic property of the Japanese NiTi alloy wire for use in orthodontics. Am J Orthod Dentofacial Orthop. 90:1–10. DOI: 10.1016/0889-5406(86)90021-1. PMID: 3460342.2. Bradley TG, Brantley WA, Culbertson BM. 1996; Differential scanning calorimetry (DSC) analyses of superelastic and nonsuperelastic nickel-titanium orthodontic wires. Am J Orthod Dentofacial Orthop. 109:589–97. DOI: 10.1016/S0889-5406(96)70070-7. PMID: 8659468.3. Aghili H, Yasssaei S, Ahmadabadi MN, Joshan N. 2015; Load deflection characteristics of nickel titanium initial archwires. J Dent (Tehran). 12:695–704. PMID: 27148381. PMCID: PMC4854749.4. Khier SE, Brantley WA, Fournelle RA. 1991; Bending properties of superelastic and nonsuperelastic nickel-titanium orthodontic wires. Am J Orthod Dentofacial Orthop. 99:310–8. DOI: 10.1016/0889-5406(91)70013-M. PMID: 2008890.5. Andreasen G, Wass K, Chan KC. 1985; A review of superelastic and thermodynamic nitinol wire. Quintessence Int. 16:623–6. PMID: 3865259.6. Kusy RP. 1997; A review of contemporary archwires: their properties and characteristics. Angle Orthod. 67:197–207. DOI: 10.1043/0003-3219(1997)067<0197:AROCAT>2.3.CO;2. PMID: 9188964.7. Kusy RP, Whitley JQ. 2007; Thermal and mechanical characteristics of stainless steel, titanium-molybdenum, and nickel-titanium archwires. Am J Orthod Dentofacial Orthop. 131:229–37. DOI: 10.1016/j.ajodo.2005.05.054. PMID: 17276864.8. Barwart O, Rollinger JM, Burger A. 1999; An evaluation of the transition temperature range of super-elastic orthodontic NiTi springs using differential scanning calorimetry. Eur J Orthod. 21:497–502. DOI: 10.1093/ejo/21.5.497. PMID: 10565090.9. Brantley WA, Eliades T. 2001. Orthodontic materials: scientific and clinical aspects. Goerge Thieme Verlag;Stuttgart: DOI: 10.1055/b-002-43889.10. Duerig TW Melton K, Stöckel D, Wayman C. 1990. Engineering aspects of shape memory alloys. Butterworth-Heinemann;London: p. 13–20. DOI: 10.1016/B978-0-7506-1009-4.50015-9.11. Meling TR, Odegaard J. 2001; The effect of short-term temperature changes on superelastic nickel-titanium archwires activated in orthodontic bending. Am J Orthod Dentofacial Orthop. 119:263–73. DOI: 10.1067/mod.2001.112451. PMID: 11244421.12. Bartzela TN, Senn C, Wichelhaus A. 2007; Load-deflection characteristics of superelastic nickel-titanium wires. Angle Orthod. 77:991–8. DOI: 10.2319/101206-423.1. PMID: 18004922.13. Lombardo L, Toni G, Stefanoni F, Mollica F, Guarneri MP, Siciliani G. 2013; The effect of temperature on the mechanical behavior of nickel-titanium orthodontic initial archwires. Angle Orthod. 83:298–305. DOI: 10.2319/040612-287.1. PMID: 22908946. PMCID: PMC8793662.14. Nakano H, Satoh K, Norris R, Jin T, Kamegai T, Ishikawa F, et al. 1999; Mechanical properties of several nickel-titanium alloy wires in three-point bending tests. Am J Orthod Dentofacial Orthop. 115:390–5. DOI: 10.1016/S0889-5406(99)70257-X. PMID: 10194282.15. Sakima MT, Dalstra M, Melsen B. 2006; How does temperature influence the properties of rectangular nickel-titanium wires? Eur J Orthod. 28:282–91. DOI: 10.1093/ejo/cji079. PMID: 16199409.16. Mirabella AD, Artun J. 1995; Risk factors for apical root resorption of maxillary anterior teeth in adult orthodontic patients. Am J Orthod Dentofacial Orthop. 108:48–55. DOI: 10.1016/S0889-5406(95)70065-X. PMID: 7598104.17. Cannon JL. 1984; Dual-flex archwires. J Clin Orthod. 18:648–9. PMID: 6592172.18. Thompson WJ. 1988; Combination anchorage technique: an update of current mechanics. Am J Orthod Dentofacial Orthop. 93:363–79. DOI: 10.1016/0889-5406(88)90095-9. PMID: 3284330.19. Sanders E, Johannessen L, Nadal J, Jäger A, Bourauel C. 2022; Comparison of multiforce nickel-titanium wires to multistrand wires without force zones in bending and torque measurements. J Orofac Orthop. 83:382–94. DOI: 10.1007/s00056-021-00321-2. PMID: 34228142.20. Lombardo L, Ceci M, Mollica F, Mazzanti V, Palone M, Siciliani G. 2019; Mechanical properties of multi-force vs. conventional NiTi archwires. J Orofac Orthop. 80:57–67. DOI: 10.1007/s00056-018-00164-4. PMID: 30610250.21. ASTM International. 2016. ASTM F2082/F2082M-16. Standard test method for determination of transformation temperature of nickel-titanium shape memory alloys by bend and free recovery. ASTM;West Conshohocken: DOI: 10.1520/f2082_f2082m.22. ASTM International. 2017. ASTM F2004-17. Standard test method for transformation temperature of nickel-titanium alloys by thermal analysis. ASTM;West Conshohocken: DOI: 10.1520/f2004-00.23. Nespoli A, Villa E, Passaretti F, Albertini F, Cabassi R, Pasquale M, et al. 2014; Non-conventional techniques for the study of phase transitions in NiTi-based alloys. J Mater Eng Perform. 23:2491–7. DOI: 10.1007/s11665-014-1105-6.24. Silness J, Loe H. 1964; Periodontal disease in pregnancy. II. Correlation between oral hygiene and periodontal condtion. Acta Odontol Scand. 22:121–35. DOI: 10.3109/00016356408993968. PMID: 14158464.25. Bourauel C, Drescher D, Thier M. 1992; An experimental apparatus for the simulation of three-dimensional movements in orthodontics. J Biomed Eng. 14:371–8. DOI: 10.1016/0141-5425(92)90081-U. PMID: 1405553.26. DIN Dentistry. 2020. Wires for use in orthodontics (ISO 15841:2014/Amd 1:2020). German version. Newark;iTeh, Inc.:27. ASTM International. 2016. ASTM F2082-06. Standard test method for determination of transformation temperature of nickel-titanium shape memory alloys by bend and free recovery. ASTM;West Conshohocken: DOI: 10.1520/f2082_f2082m.28. Sifakakis I, Eliades T. 2017; Laboratory evaluation of orthodontic biomechanics: the clinical applications revisited. Semin Orthod. 23:382–9. DOI: 10.1053/j.sodo.2017.07.008.29. Krishnan V, Kumar KJ. 2004; Mechanical properties and surface characteristics of three archwire alloys. Angle Orthod. 74:825–31. DOI: 10.1043/0003-3219(2004)074<0825:MPASCO>2.0.CO;2. PMID: 15673147.30. Pelton AR, Gong XY, Duerig T. 2004. Fatigue testing of diamond-shaped specimens. Paper presented at: International Conference on Shape Memory and Superelastic Technologies, SMST-2003. 2003 May 5-8; Pacific Grove, USA. SMST Society, Inc.;Menlo Park:31. Theodorou CI, Kuijpers-Jagtman AM, Bronkhorst EM, Wagener FADTG. 2019; Optimal force magnitude for bodily orthodontic tooth movement with fixed appliances: a systematic review. Am J Orthod Dentofacial Orthop. 156:582–92. DOI: 10.1016/j.ajodo.2019.05.011. PMID: 31677666.32. Proffit W. Proffit W, Fields H, Larson B, Sarver D, editors. 2018. The biologic basis of orthodontic therapy. Contemporary orthodontics. 6th ed. Elsevier Mosby;Louis: p. 278.33. Sifakakis I, Pandis N, Makou M, Eliades T, Bourauel C. 2010; A comparative assessment of the forces and moments generated at the maxillary incisors between conventional and self-ligating brackets using a reverse curve of Spee NiTi archwire. Aust Orthod J. 26:127–33. PMID: 21175021.34. Ibe DM, Segner D. 1998; Superelastic materials displaying different force levels within one archwire. J Orofac Orthop. 59:29–38. DOI: 10.1007/BF01321553. PMID: 9505053.35. Elayyan F, Silikas N, Bearn D. 2008; Ex vivo surface and mechanical properties of coated orthodontic archwires. Eur J Orthod. 30:661–7. DOI: 10.1093/ejo/cjn057. PMID: 19011166.36. Bradley TG, Maslowski MJ, Toth JM, Monaghan P. 2003; Reduction of mechanical properties of NiTi wires due to clinical use. J Dent Res. 82(special issue A):Abstract 1538.37. Obaisi NA, Galang-Boquiren MT, Evans CA, Tsay TG, Viana G, Berzins D, et al. 2016; Comparison of the transformation temperatures of heat-activated Nickel-Titanium orthodontic archwires by two different techniques. Dent Mater. 32:879–88. DOI: 10.1016/j.dental.2016.03.017. PMID: 27183921.38. Mehta ASK. 2015. Thermomechanical characterization of variable force NiTi orthodontic archwires [Master's Theses]. Marquette University;Milwaukee:39. Chen JT, Duerig TW, Pelton AR, Stöckel D. 1995; An apparatus to measure the shape memory properties of Nitinol tubes for medical applications. J Phys IV. 5(C8):1247–52. DOI: 10.1051/jp4/1995581247.40. Butler J, Tiernan P, Tofail SAM, Gandhi A. 2010. Probing martensitic transition in Nitinol wire: a comparison of X‐ray diffraction and other techniques. Paper presented at: International Conference on Advances in Materials and Processing Technologies. AIP Conference Proceedings. 2010 Jul 21-22; Portland, USA. American Institute of Physics;Melville: DOI: 10.1063/1.3552318.41. Norwich DW. 2010. A Study of the properties of a high temperature binary Nitinol alloy above and below its martensite to austenite transformation temperature. SAES Memry Corporation;Bethel:42. Pelton AR, Dicello J, Miyazaki S. 2000; Optimisation of processing and properties of medical grade Nitinol wire. Minim Invasive Ther Allied Technol. 9:107–18. DOI: 10.3109/13645700009063057.43. Longman CM, Pearson GJ. 1987; Variations in tooth surface temperature in the oral cavity during fluid intake. Biomaterials. 8:411–4. DOI: 10.1016/0142-9612(87)90016-0. PMID: 3676430.44. Otsuka K. Duerig TW, Melton KN, Stöckel D, Wayman CM, editors. 1990. Introduction to the R-phase transition. Engineering aspects of shape memory alloys. Butterworth-Heinemann Ltd.;London: p. 36–45. DOI: 10.1016/B978-0-7506-1009-4.50007-X.45. Biermann MC, Berzins DW, Bradley TG. 2007; Thermal analysis of as-received and clinically retrieved copper-nickel-titanium orthodontic archwires. Angle Orthod. 77:499–503. DOI: 10.2319/0003-3219(2007)077[0499:TAOAAC]2.0.CO;2. PMID: 17465660.46. Amini F, Rakhshan V, Pousti M, Rahimi H, Shariati M, Aghamohamadi B. 2012; Variations in surface roughness of seven orthodontic archwires: an SEM-profilometry study. Korean J Orthod. 42:129–37. DOI: 10.4041/kjod.2012.42.3.129. PMID: 23112943. PMCID: PMC3481981.47. Usui T, Iwata T, Miyake S, Otsuka T, Koizumi S, Shirakawa N, et al. 2018; Mechanical and frictional properties of aesthetic orthodontic wires obtained by hard chrome carbide plating. J Dent Sci. 13:151–9. DOI: 10.1016/j.jds.2017.07.003. PMID: 30895111. PMCID: PMC6388802. PMID: 9108157bf2c749f7a1488293882d7278.48. Pelsue BM, Zinelis S, Bradley TG, Berzins DW, Eliades T, Eliades G. 2009; Structure, composition, and mechanical properties of Australian orthodontic wires. Angle Orthod. 79:97–101. DOI: 10.2319/022408-110.1. PMID: 19123699.49. Brantley W. Brantley W, Eliades T, editors. 2001. Orthodontic wires. Orthodontic materials. Thieme;Stuttgart: p. 78–100. DOI: 10.1055/b-002-43889.50. Thompson SA. 2000; An overview of nickel-titanium alloys used in dentistry. Int Endod J. 33:297–310. DOI: 10.1046/j.1365-2591.2000.00339.x. PMID: 11307203.51. Kusy RP, Whitley JQ, Prewitt MJ. 1991; Comparison of the frictional coefficients for selected archwire-bracket slot combinations in the dry and wet states. Angle Orthod. 61:293–302. Erratum in: Angle Orthod 1993;63:164. DOI: 10.1043/0003-3219(1991)061<0293:COTFCF>2.0.CO;2. PMID: 1763840.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Effects of heat treatment on the load-deflection properties of nickel-titanium wire

- Mechanical properties of nickel titanium and steel alloys under stress- strain test

- Three point bending test of recycled Nickel-Titanium alloy wires

- The effect of heat sterilization on the surface topography and the tensile properties in various nickel titanium wires including a Korean product

- Effects of recycling on the mechanical properties and the surface topography of Nickel-Titanium alloy wires