J Dent Rehabil Appl Sci.

2022 Sep;38(3):138-149. 10.14368/jdras.2022.38.3.138.

Literature review on fractography of dental ceramics

- Affiliations

-

- 1Department of Prosthodontics and Research Institute of Oral Science, College of Dentistry, Gangneung-Wonju National University, Gangneung, Republic of Korea

- 2Department of Dentistry, Gangneung Asan Hospital, University of Ulsan College of Medicine, Gangneung, Republic of Korea

- KMID: 2535019

- DOI: http://doi.org/10.14368/jdras.2022.38.3.138

Abstract

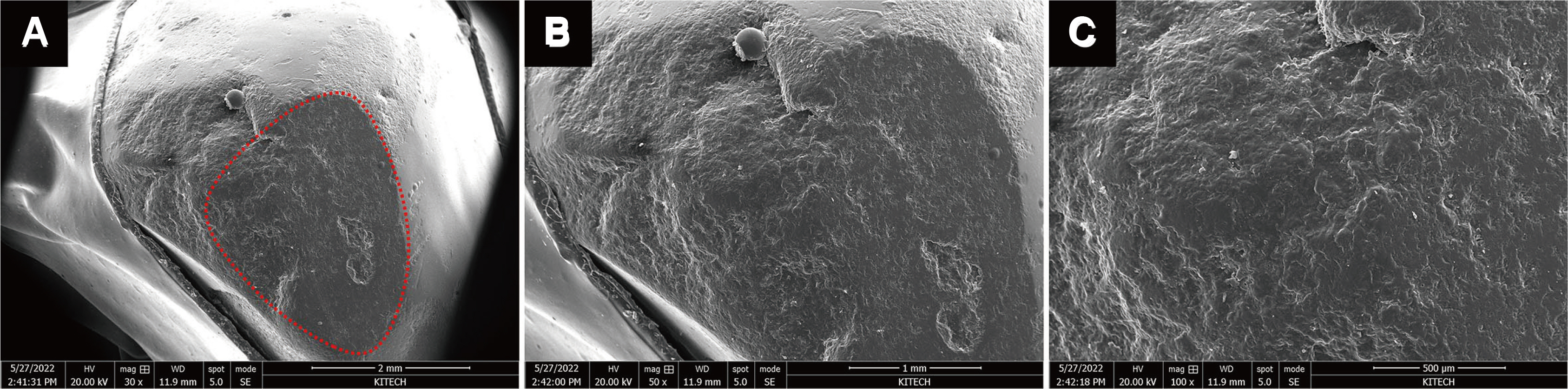

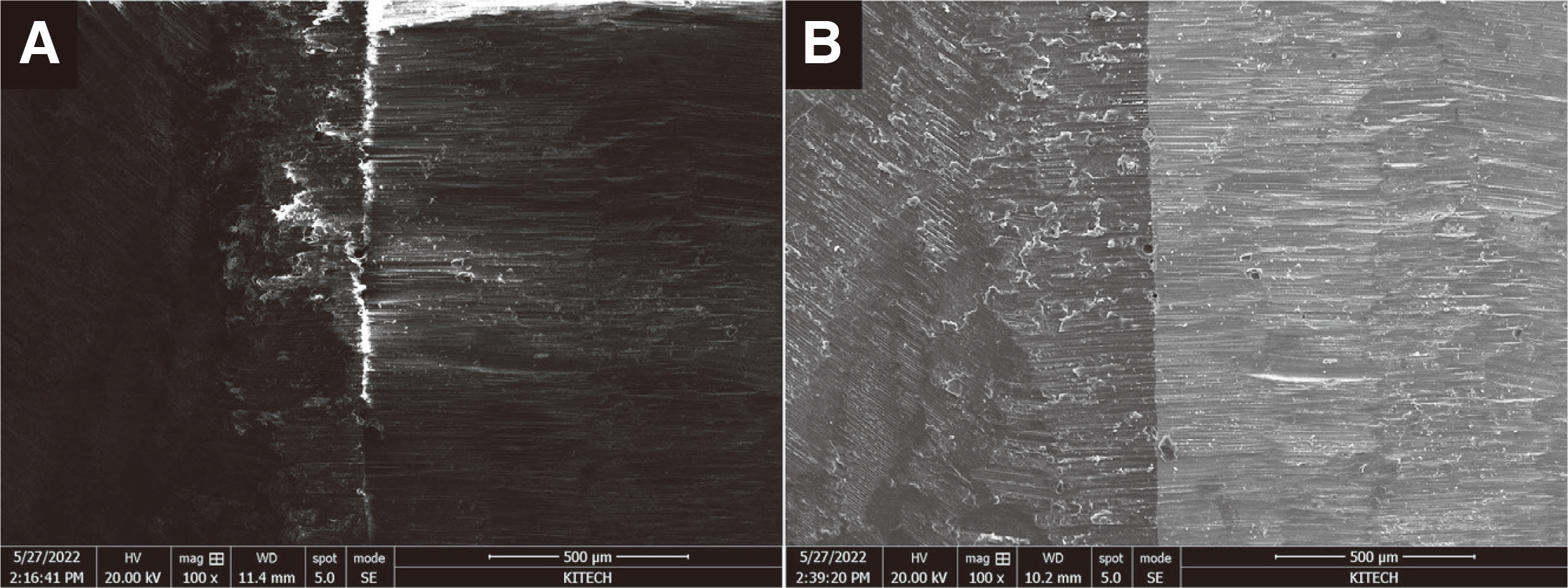

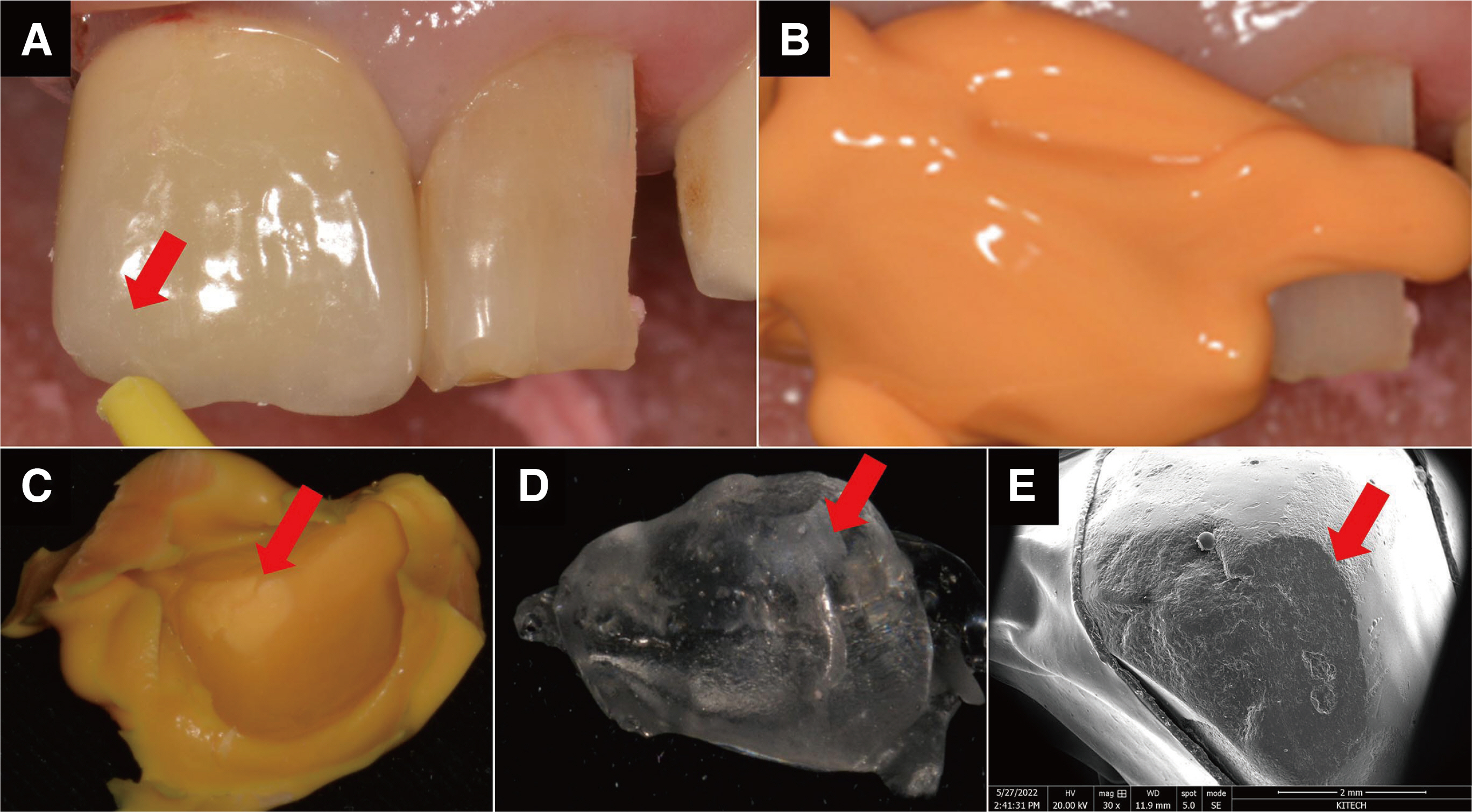

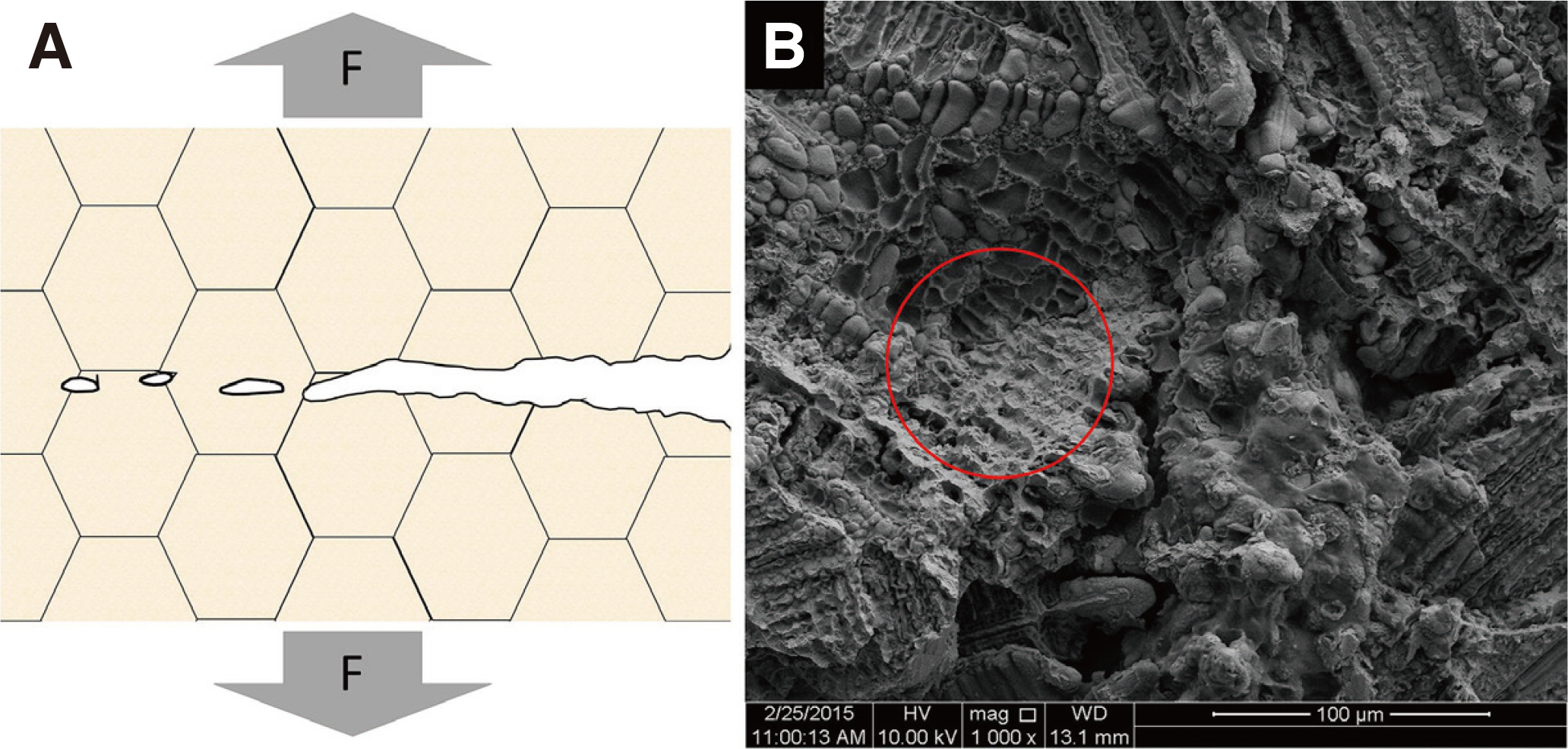

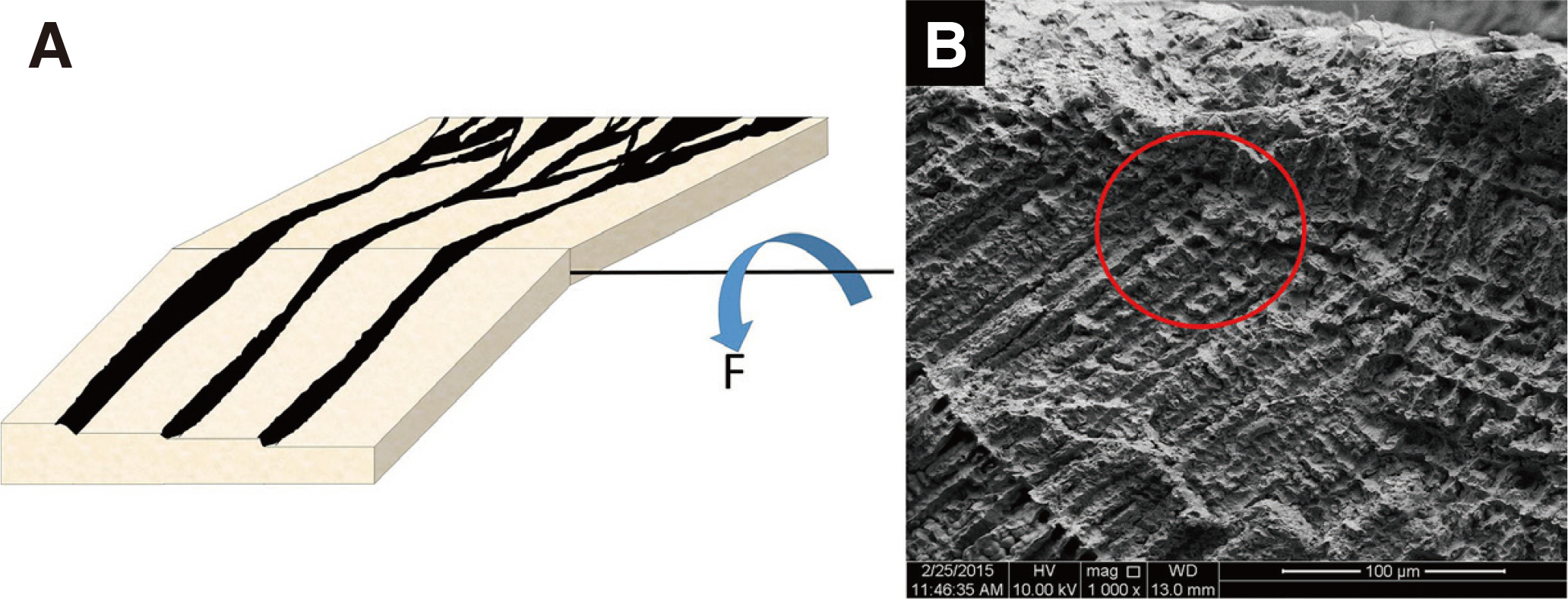

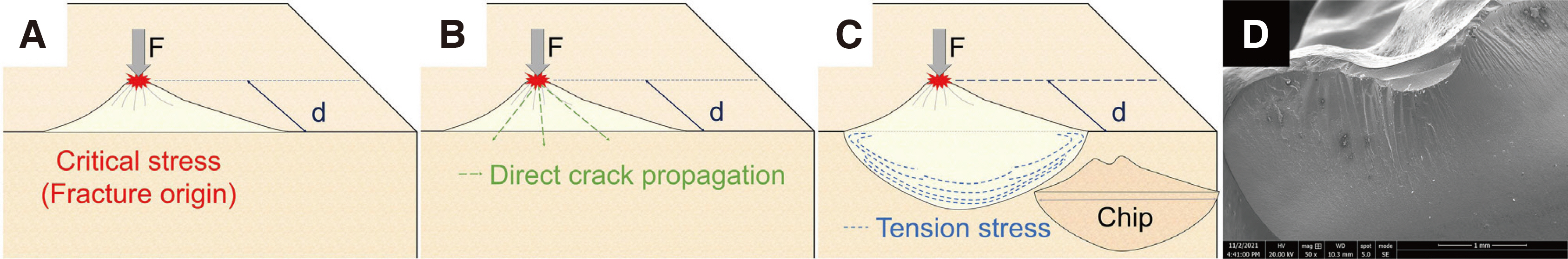

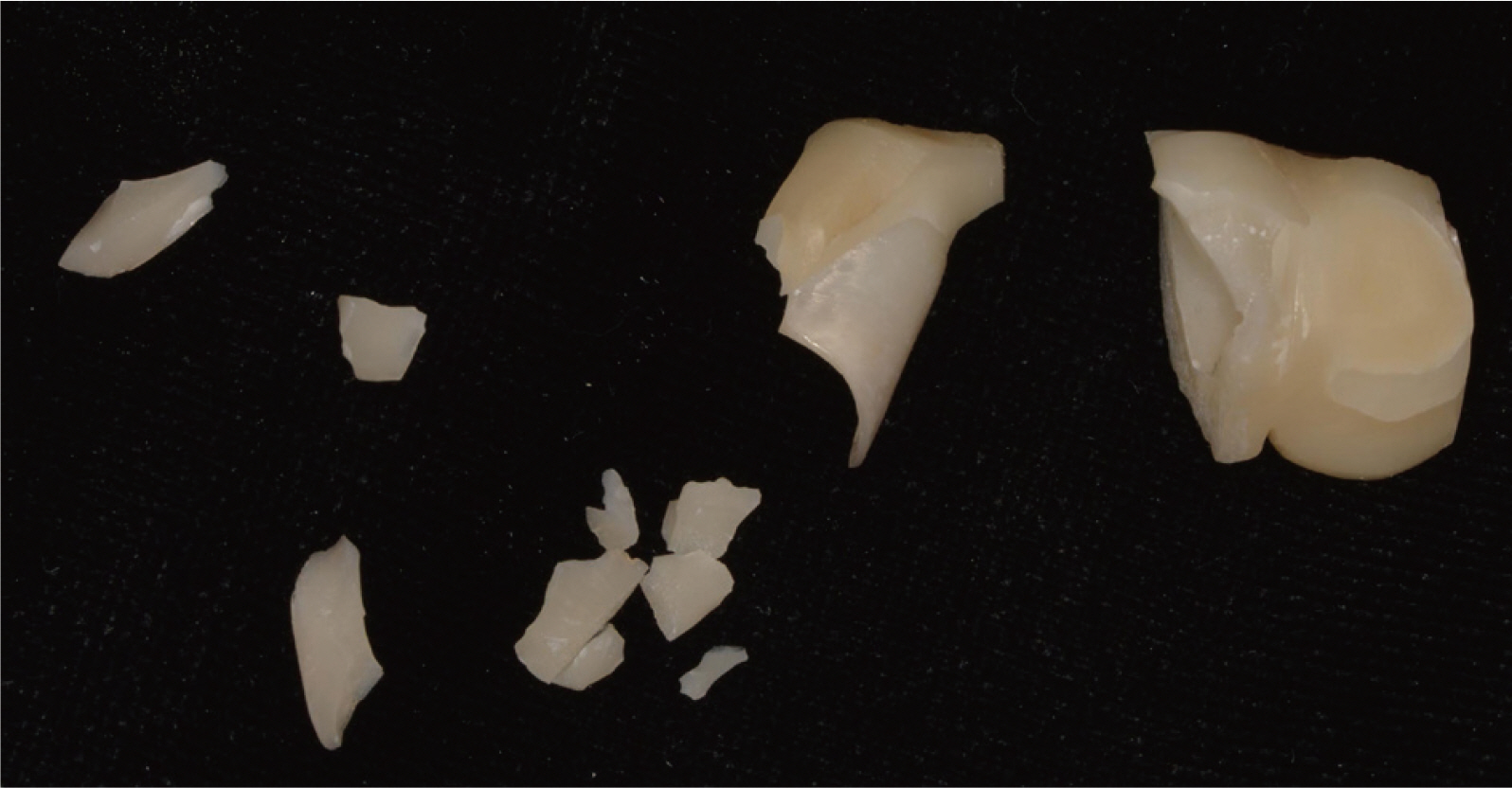

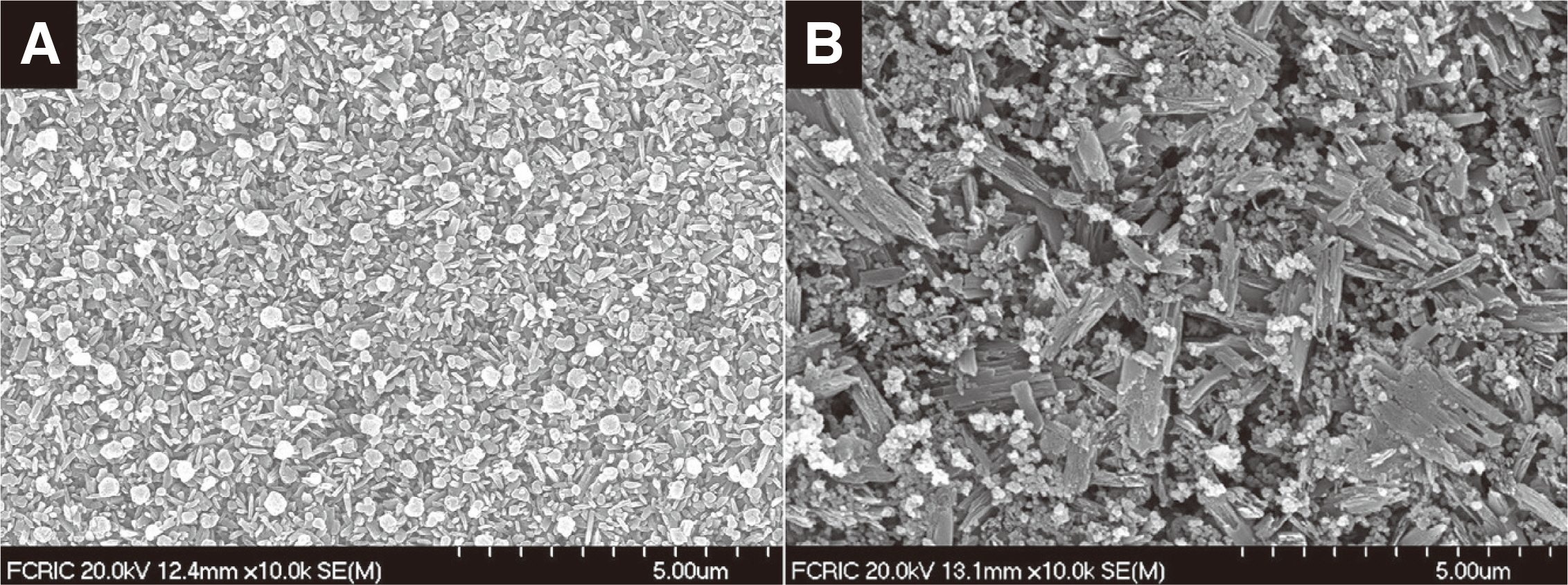

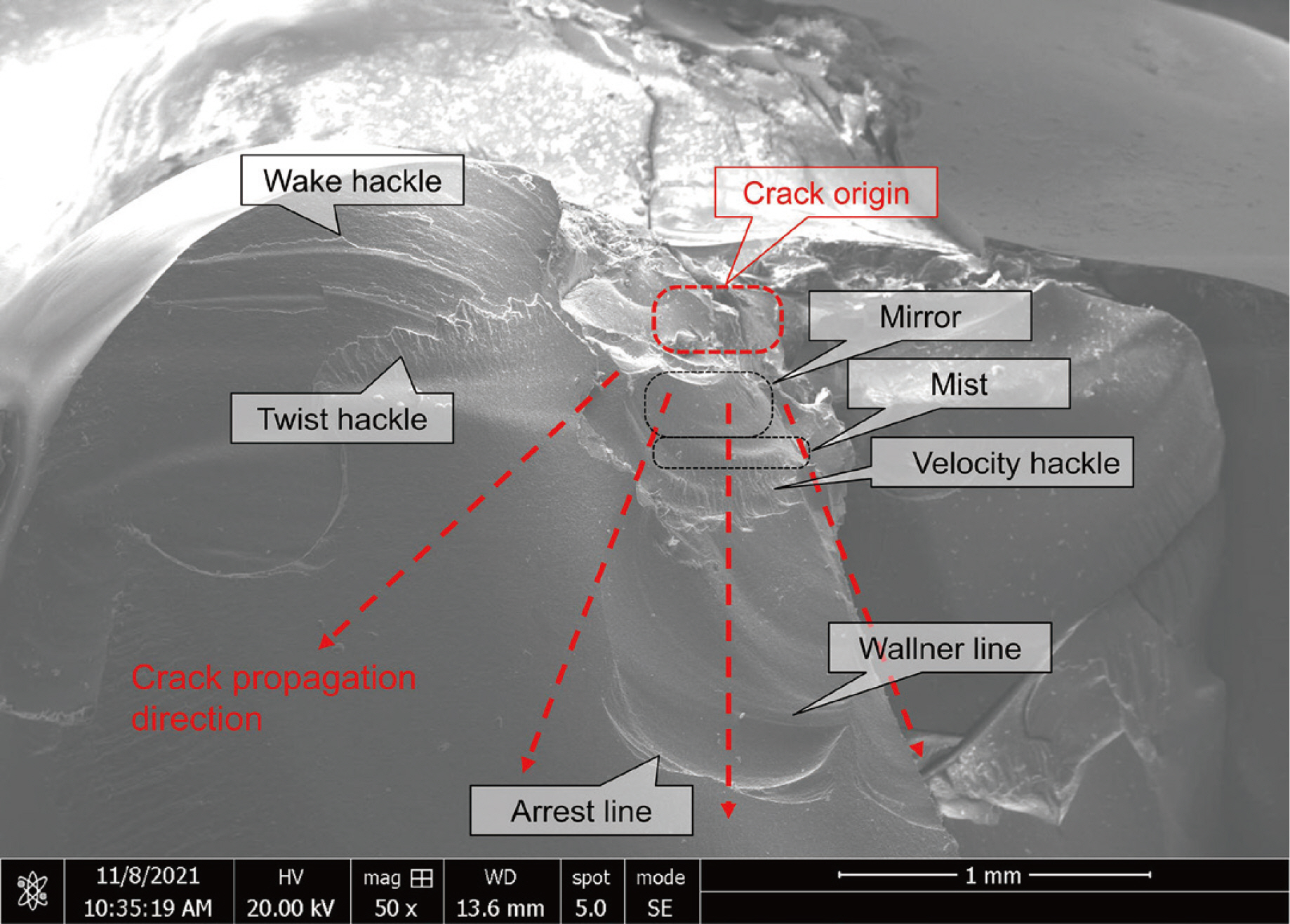

- The clinical applicability of ceramics can be increased by analyzing the causes of fractures after fracture testing of dental ceramics. Fractography to analyze the cause of fracture of dental ceramics is being widely applied with the development of imaging technologies such as scanning electron microscopy. Setting the experimental conditions is important for accurate interpretation. The fractured specimens should be stored and cleaned to avoid contamination, and metal pretreatment is required for better observation. Depending on the type of fracture, there are dimple rupture, cleavage, and decohesive rupture mainly observed in metals, and fatigue fractures and conchoidal fractures observed in ceramics. In order to reproduce fatigue fracture in the laboratory, which is the main cause of fracture of ceramics, a dynamic loading for observing slow crack growth is essential, and the load conditions and number of loads must be appropriately set. A typical characteristic of a fracture surface of ceramic is a hackle, and the causes of fracture vary depending on the shape of hackle. Fractography is a useful method for in-depth understanding of fractures of dental ceramics, so it is necessary to follow the exact experimental procedure and interpret the results with caution.

Keyword

Figure

Reference

-

References

1. Lawson NC, Burgess JO. 2014; Dental ceramics: a current review. Compend Contin Educ Dent. 35:161–6. PMID: 24773195.2. Lynch SP, Moutsos S. 2006; A brief history of fractography. J Fail Anal Prev. 6:54–69. DOI: 10.1361/154770206X156231.

Article3. Kemmenoe BH, Bullock GR. 1983; Structure analysis of sputter coated and ion beam sputter coated films: a comparative study. J Microsc. 132:153–63. DOI: 10.1111/j.1365-2818.1983.tb04267.x. PMID: 6358510.4. Mills K, Davis JR, Destefani JD, Dieterich DA. 1998. ASM Handbook. Vol. 12. Fractography. Available from: https://docero.tips/doc/asm-handbookvolume-12-fractography-1998s-16d34vnnvl. updated 2022 Sep 1.5. Hein LR, Campos KA, Caltabiano PC, Kostov KG. 2013; A brief discussion about image quality and SEM methods for quantitative fractography of polymer composites. Scanning. 35:196–204. DOI: 10.1002/sca.21048. PMID: 22915360.

Article6. Scherrer SS, Quinn JB, Quinn GD, Wiskott HW. 2007; Fractographic ceramic failure analysis using the replica technique. Dent Mater. 23:1397–404. DOI: 10.1016/j.dental.2006.12.002. PMID: 17270267. PMCID: PMC2077838.

Article7. Yamini S, Young R. 1979; Crack propagation in and fractography of epoxy resins. J Mater Sci. 14:1609–14. DOI: 10.1007/BF00569280.

Article8. Echlin P. 2011. Handbook of sample preparation for scanning electron microscopy and X-ray microanalysis. 1st ed. Springer Science & Business Media;New York: DOI: 10.1007/b100727_3.9. Young R, Buxbaum A, Peterson B, Schampers R. 2008; In-situ sample preparation and modeling of SEMSTEM imaging. Microsc Microanal. 14:1000–1. DOI: 10.1017/S1431927608081713.

Article10. Scherrer SS, Quinn JB, Quinn GD, Kelly JR. 2006; Failure analysis of ceramic clinical cases using qualitative fractography. Int J Prosthodont. 19:185–92. PMID: 16602369.11. Mecholsky JJ Jr. 1995; Fractography: Determining the sites of fracture initiation. Dent Mater. 11:113–6. DOI: 10.1016/0109-5641(95)80045-X. PMID: 8621031.

Article12. Sujata M, Jagannathan N, Raghavendra K, Manjunatha CM, Bhaumik SK. 2013; Fatigue fracture of a compressor disc of an aerogenine. J Fail Anal Preven. 13:437–44. DOI: 10.1007/s11668-013-9688-z.13. Hasnaoui A, Van Swygenhoven H, Derlet PM. 2003; Dimples on nanocrystalline fracture surfaces as evidence for shear plane formation. Science. 300:1550–2. DOI: 10.1126/science.1084284. PMID: 12791986.

Article14. Liu P, Li Y, Geng H, Wang J. 2007; Microstructure characteristics in TIG welded joint of Mg/Al dissimilar materials. Mater Lett. 61:1288–91. DOI: 10.1016/j.matlet.2006.07.010.

Article15. De Saude J, Sun SD, Sharp P, Luzin V, Klein A, Wang C, Brandt M. 2016; Fatigue and fracture behavior of laser clad repair of AerMet® 100 ultra-high strength steel. Int J Fatig. 85:18–30. DOI: 10.1016/j.ijfatigue.2015.11.021.

Article16. Salazar Marocho SM, Studart AR, Bottino MA, Della Bona A. 2010; Mechanical strength and subcritical crack growth under wet cyclic loading of glass-infiltrated dental ceramics. Dent Mater. 26:483–90. DOI: 10.1016/j.dental.2010.01.007. PMID: 20303160.

Article17. Kelly JR, Cesar PF, Scherrer SS, Della Bona A, van Noort R, Tholey M, Vichi A, Lohbauer U. 2017; ADM guidance-ceramics: Fatigue principles and testing. Dent Mater. 33:1192–204. DOI: 10.1016/j.dental.2017.09.006. PMID: 29017761.

Article18. Taskonak B, Griggs JA, Mecholsky JJ Jr, Yan JH. 2008; Analysis of subcritical crack growth in dental ceramics using fracture mechanics and fractography. Dent Mater. 24:700–7. DOI: 10.1016/j.dental.2007.08.001. PMID: 17845817. PMCID: PMC2358925.

Article19. Kirsten A, Begand S, Oberbach T, Telle R, Fischer H. 2010; Subcritical crack growth behavior of dispersion oxide ceramics. J Biomed Mater Res B Appl Biomater. 95:202–6. DOI: 10.1002/jbm.b.31703. PMID: 20737435.

Article20. Song XF, Yin L, Peng JH, Lin B. 2013; Cutting characteristics of dental glass ceramics during in vitro dental abrasive adjusting using a high-speed electric handpiece. Ceram Int. 39:6237–49. DOI: 10.1016/j.ceramint.2013.01.045.

Article21. Song XF, Ma HR, He YP, Yin L. 2022; Soft machininginduced surface and edge chipping damage in precrystalized lithium silicate glass ceramics. J Mech Behav Biomed Mater. 131:105224. DOI: 10.1016/j.jmbbm.2022.105224. PMID: 35413493.

Article22. Teixeira EC, Piascik JR, Stoner BR, Thompson JY. 2007; Dynamic fatigue and strength characterization of three ceramic materials. J Mater Sci Mater Med. 18:1219–24. DOI: 10.1007/s10856-007-0131-4. PMID: 17277977.

Article23. Gonzaga CC, Cesar PF, Miranda WG Jr, Yosimura HN. 2011; Slow crack growth and reliability of dental ceramics. Dent Mater. 27:394–406. DOI: 10.1016/j.dental.2010.10.025. PMID: 21185074.

Article24. Lee YJ, Huh YH, Ko KH, Park CJ, Cho LR. 2022; Evaluation of various polishing systems for lithium disilicate glass-ceramics. Eur J Prosthodont Restor Dent. 30:188–99. DOI: 10.1922/EJPRD_2332Lee12. PMID: 34862863.25. Bravo-León A, Jiménez-Melendo M, Domínguez-Rodríguez A. 1992; Mechanical and microstructural aspects of the high temperature plastic deformation of yttria-stabilized zirconia polycrystals. Acta Metal Mater. 40:2717–26. DOI: 10.1016/0956-7151(92)90342-C.

Article26. Eichle J, Rödel J, Eisele U, Hoffman M. 2007; Effect of grain size on mechanical properties of submicrometer 3Y-TZP: fracture strength and hydrothermal degradation. J Am Ceram Soc. 90:2830–6. DOI: 10.1111/j.1551-2916.2007.01643.x.

Article27. Smith TB, Kelly JR, Tesk JA. 1994; In vitro fracture behavior of ceramic and metal-ceramic restorations. J Prosthodont. 3:138–44. DOI: 10.1111/j.1532-849X.1994.tb00144.x. PMID: 7874255.

Article28. Marx R, Jungwirth F, Walter PO. 2004; Threshold intensity factors as lower boundaries for crack propagation in ceramics. Biomed Eng Online. 3:41. DOI: 10.1186/1475-925X-3-41. PMID: 15548323. PMCID: PMC539288.

Article29. Quinn GD. 2007. Fractography of ceramics and glasses. 3rd ed. National Institute of Standards and Technology;Washington: p. 233–5. DOI: 10.1111/j.1532-849x.1994.tb00144.x.30. Cesar PF, Della Bona A, Scherrer SS, Tholey M, van Noort R, Vichi A, Kelly R, Lohbauer U. 2017; ADM guidance-Ceramics: Fracture toughness testing and method selection. Dent Mater. 33:575–84. DOI: 10.1016/j.dental.2017.03.006. PMID: 28392020.

Article31. Scherrer SS, Cattani-Lorente M, Vittecoq E, de Mestral F, Griggs JA, Wiskott HW. 2011; Fatigue behavior in water of Y-TZP zirconia ceramics after abrasion with 30 μm silica-coated alumina particles. Dent Mater. 27:e28–42. DOI: 10.1016/j.dental.2010.10.003. PMID: 21056462. PMCID: PMC3249662.32. Quinn GD, Eichler J, Eisele U, Rodel J. 2004; Fracture mirrors in nanoscale 3Y TZP. J Am Ceram Soc. 87:513–6. DOI: 10.1111/j.1551-2916.2004.00513.x.33. Preis V, Behr M, Hahnel S, Handel G, Rosentritt M. 2012; In vitro failure and fracture resistance of veneered and full-contour zirconia restorations. J Dent. 40:921–8. DOI: 10.1016/j.jdent.2012.07.010. PMID: 22835417.

Article34. Quinn GD. 2020. Fractography of ceramics and glasses. 3rd ed. National Institute of Standards and Technology;Washington: p. 108–256. DOI: 10.1016/j.jdent.2012.07.010.35. Quinn JB, Quinn GD, Kelly JR, Scherrer SS. 2005; Fractographic analyses of three ceramic whole crown restoration failures. Dent Mater. 21:920–9. DOI: 10.1016/j.dental.2005.01.006. PMID: 15882898.

Article36. Scherrer SS, Quinn JB, Quinn GD, Kelly JR. 2006; Failure analysis of ceramic clinical cases using qualitative fractography. Int J Prosthodont. 19:185–92. PMID: 16602369.37. Scherrer SS, Lohbauer U, Della Bona A, Vichi A, Tholey MJ, Kelly JR, van Noort R, Cesar PF. 2017; ADM guidance-Ceramics: Guidance to the use of fractography in failure analysis of brittle materials. Dent Mater. 33:599–620. DOI: 10.1016/j.dental.2017.03.004. PMID: 28400062.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- The effet of cooling rate on the residual stresses in the veneer ceramics of zirconia-ceramic restorations: a literature review

- The effect of repeated firings on the color change and surface roughness of dental ceramics

- A STUDY ON THE STAIN RESISTANCE OF DENTAL CERAMICS FOR ALL CERAMIC CROWN

- The effect of repeated firings on the color change of dental ceramics using different glazing methods

- Spectrophotometic analysis of the influence of substrate on the color of dental ceramics