Korean J Orthod.

2020 Nov;50(6):401-406. 10.4041/kjod.2020.50.6.401.

Comparison of slot sizes and parallelism of metal brackets manufactured through metal injection molding and computerized numerical control

- Affiliations

-

- 1Private Practice, Gunsan, Korea

- 2Department of Orthodontics, College of Dentistry, Wonkwang University, Iksan, Korea

- KMID: 2508448

- DOI: http://doi.org/10.4041/kjod.2020.50.6.401

Abstract

Objective

To investigate and compare the slot sizes and parallelism of metal injection molding (MIM) and computerized numerical control (CNC) brackets.

Methods

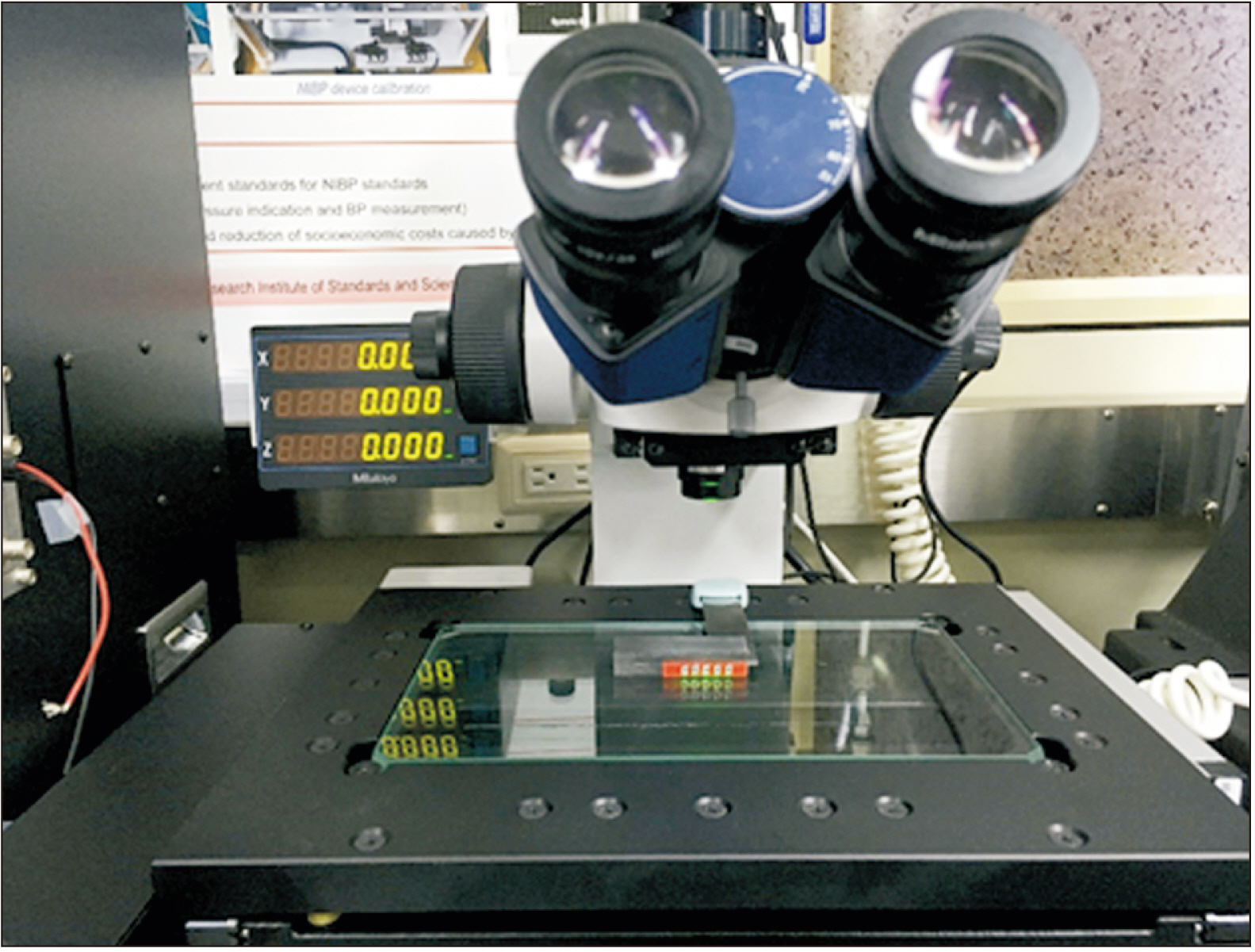

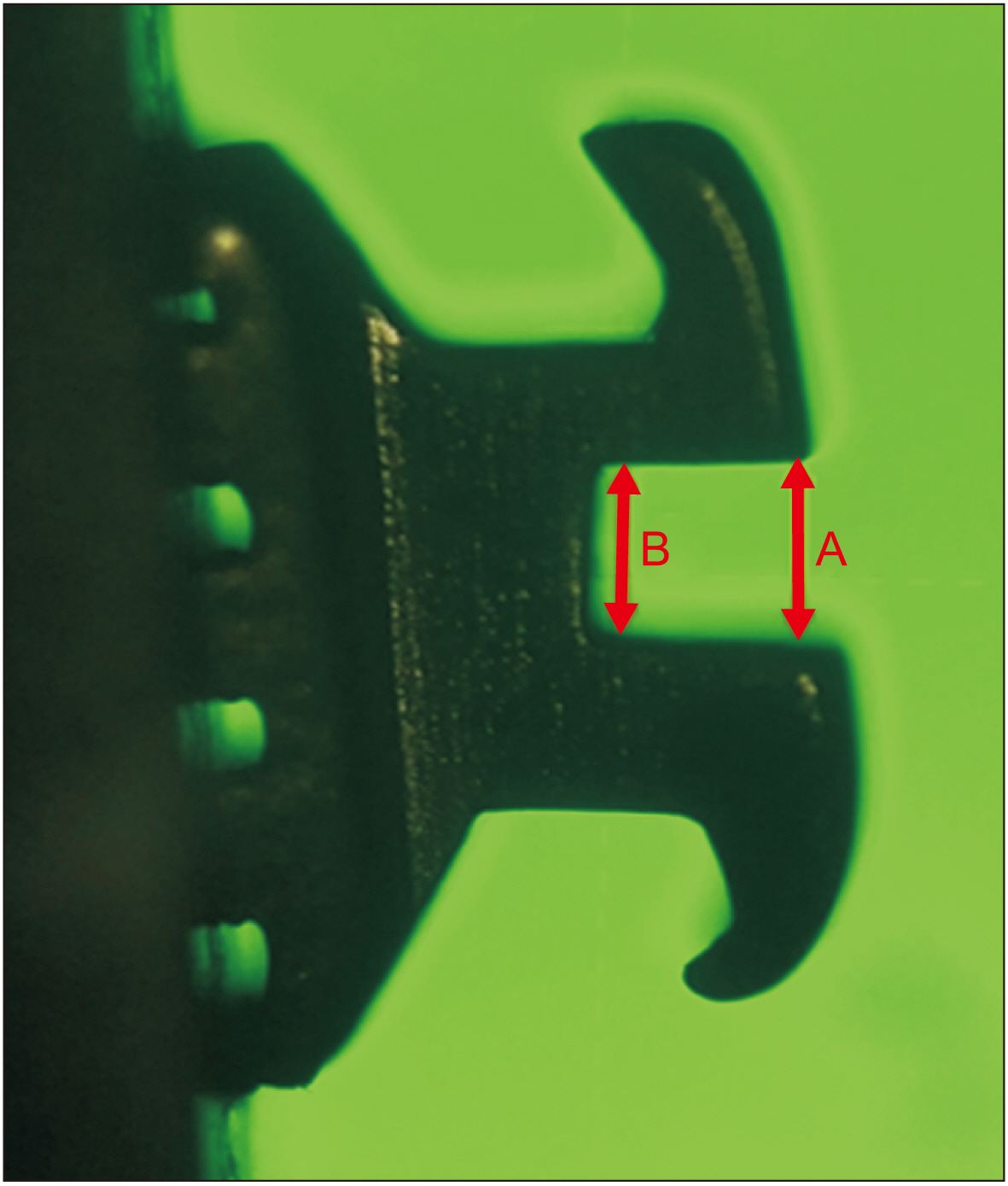

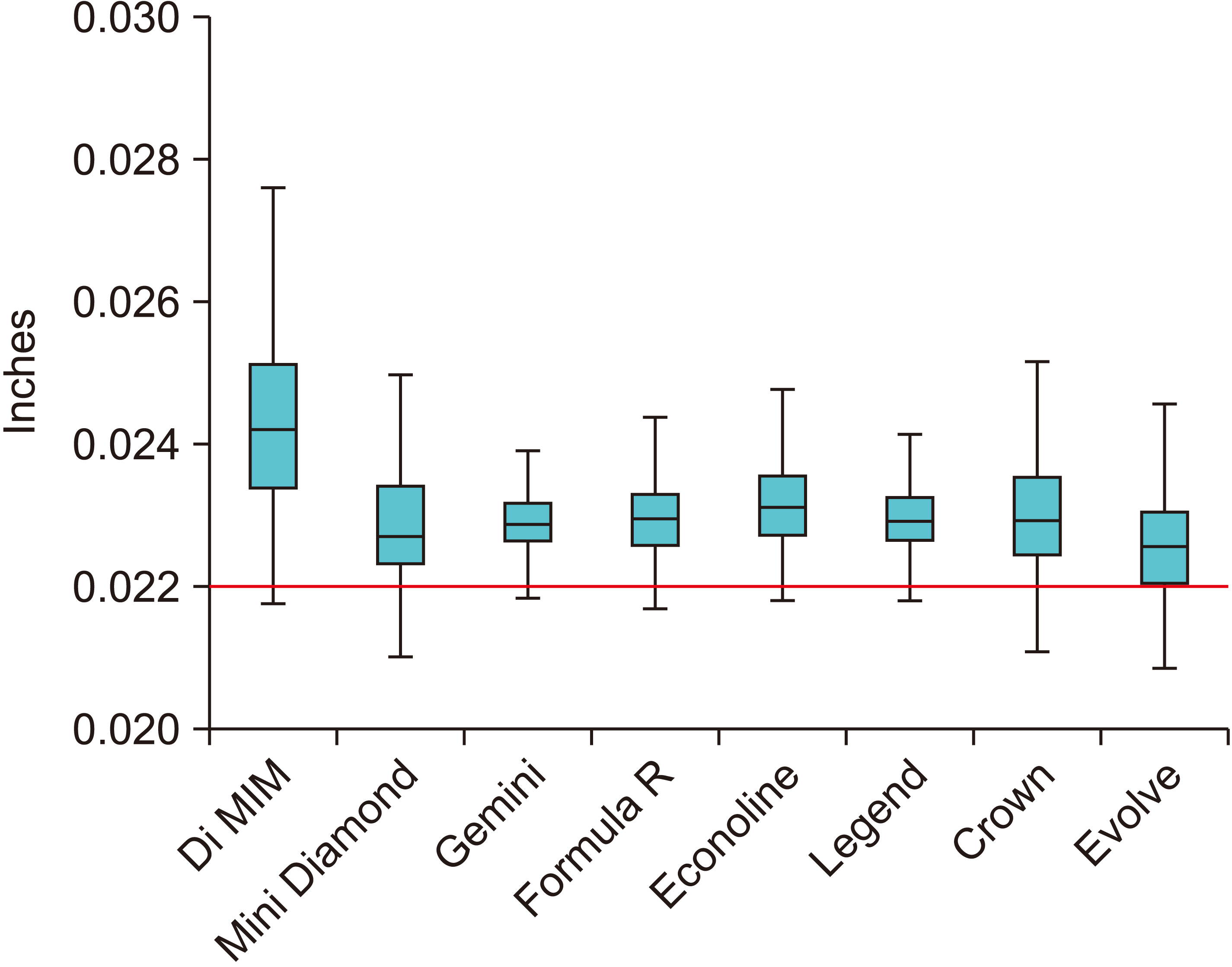

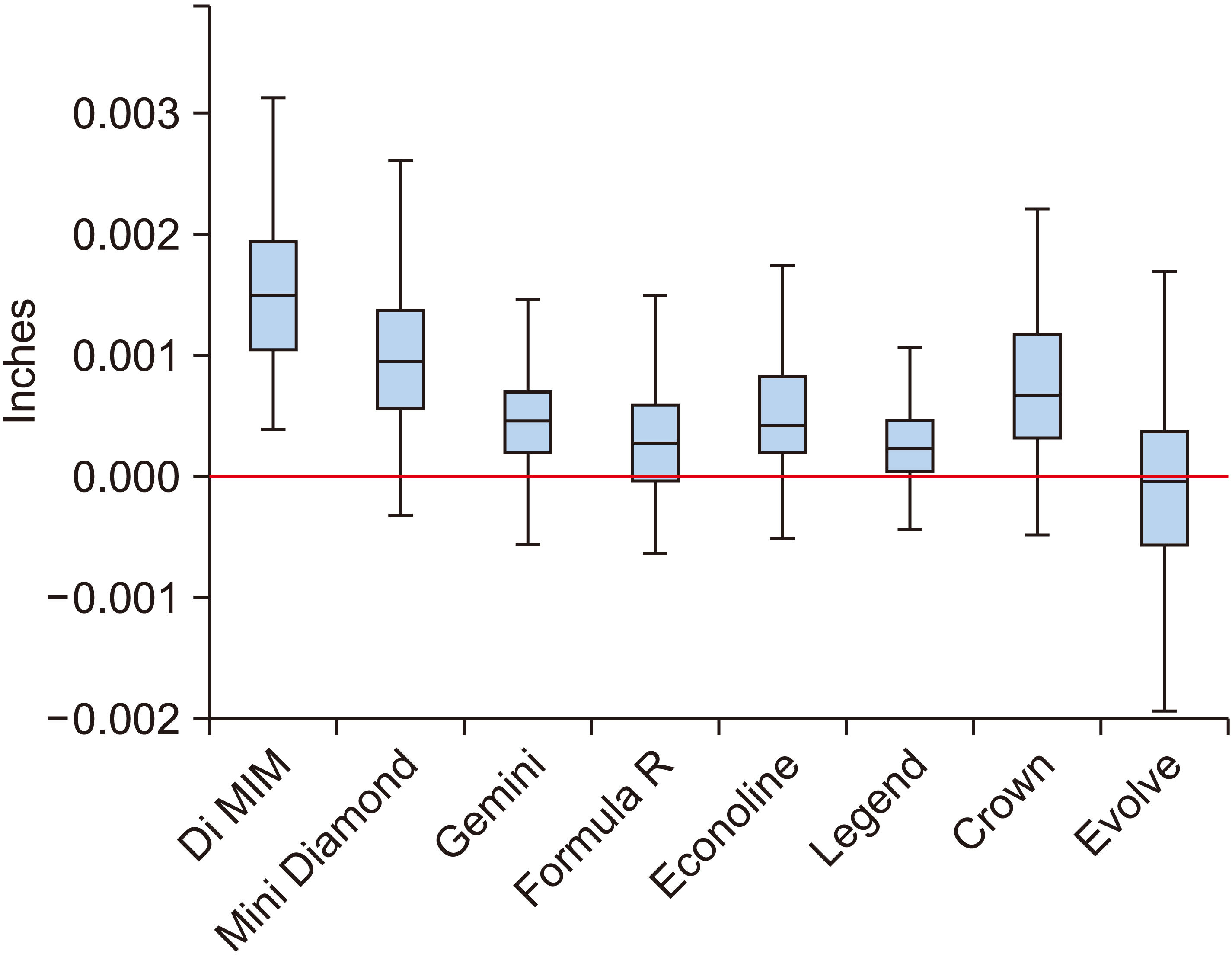

The following four MIM bracket series with 0.022-inch (in) slots were selected for investigation: Di MIM mini Twin (Ortho Organizers), Mini Diamond Roth (Ormco), Gemini MBT (3M Unitek), and Formula R Roth (Tomy). The following four CNC bracket series with 0.022-in slots were selected for investigation: Econoline MBT (Adenta), Legend mini MBT (GC Orthodontics), Crown mini MBT (Adenta), and Evolve MBT (DB Orthodontics). The slot dimensions were measured using an optical microscope (XTCam-D310M; Mitutoyo) with a resolution of 1 μm. The results were statistically analyzed using one-way analysis of variance and the Tukey post-hoc test with a significance level of 0.05.

Results

The results indicated that all the investigated slot sizes were oversized with respect to the manufacturers’ specifications (0.022 in). Among the eight bracket series, the Di MIM bracket (MIM) was the most oversized by 10.4%, whereas the Evolve bracket (CNC) was the least oversized by 2.6%. The slots in seven of the bracket series had divergent walls instead of parallel ones. The Evolve bracket alone had parallel slot walls.

Conclusions

Regardless of the manufacturing method, all the slot sizes of the brackets investigated in this study were significantly oversized; most of the slot walls were nonparallel, except for those of the Evolve bracket. This study could not establish that the CNC method was more accurate than the MIM method in manufacturing bracket slots.

Figure

Reference

-

1. Silver M, Griffin AC Jr, Azzopardi L, Masoud MI, Tokede O, Griffin AC 3rd. 2018; Novel methods reveal that parallelism contributes to the functional vertical slot dimension in ceramic and metal brackets. Angle Orthod. 88:812–8. DOI: 10.2319/010518-10.1. PMID: 30124321.

Article2. Proffit WR, Fields HW, Sarver DM. 2013. Contemporary orthodontics. 5th ed. Mosby Elsevier;St. Louis:3. Bennett JC. 2010. Fundamentals of orthodontic bracket selection: a user guide. 2nd ed. Le Grande Publishing;London:4. Alexander RG. 2008. The 20 principles of the Alexander discipline. Quintessence Publishing;Chicago:5. Brown P, Wagner W, Choi H. 2015; Orthodontic bracket slot dimensions as measured from entire bracket series. Angle Orthod. 85:678–82. DOI: 10.2319/042814-307.1. PMID: 25264581.

Article6. Eliades T, Zinelis S, Bourauel C, Eliades G. 2008; Manufacturing of orthodontic brackets: a review of metallurgical perspectives and applications. Recent Pat Mater Sci. 1:135–9. DOI: 10.2174/1874464810801020135.

Article7. Zinelis S, Annousaki O, Makou M, Eliades T. 2005; Metallurgical characterization of orthodontic brackets produced by Metal Injection Molding (MIM). Angle Orthod. 75:1024–31. DOI: 10.1043/0003-3219(2005)75[1024:MCOOBP]2.0.CO;2. PMID: 16448250.8. Cash AC, Good SA, Curtis RV, McDonald F. 2004; An evaluation of slot size in orthodontic brackets--are standards as expected? Angle Orthod. 74:450–3. DOI: 10.1043/0003-3219(2004)074<0450:AEOSSI>2.0.CO;2. PMID: 15387021.9. Kusy RP, Whitley JQ. 1999; Assessment of second-order clearances between orthodontic archwires and bracket slots via the critical contact angle for binding. Angle Orthod. 69:71–80. DOI: 10.1043/0003-3219(1999)069<0071:AOSOCB>2.3.CO;2. PMID: 10022188.10. Bhalla NB, Good SA, McDonald F, Sherriff M, Cash AC. 2010; Assessment of slot sizes in self-ligating brackets using electron microscopy. Aust Orthod J. 26:38–41. PMID: 20575198.11. Major TW, Carey JP, Nobes DS, Major PW. 2010; Orthodontic bracket manufacturing tolerances and dimensional differences between select self-ligating brackets. J Dent Biomech. 2010:781321. DOI: 10.4061/2010/781321. PMID: 20981299. PMCID: PMC2958443.12. Siatkowski RE. 1999; Loss of anterior torque control due to variations in bracket slot and archwire dimensions. J Clin Orthod. 33:508–10. PMID: 10895655.13. Eliades T. 2007; Orthodontic materials research and applications: part 2. Current status and projected future developments in materials and biocompatibility. Am J Orthod Dentofacial Orthop. 131:253–62. DOI: 10.1016/j.ajodo.2005.12.029. PMID: 17276868.

Article14. McLaughlin RP, Bennett JC. 2015; Evolution of treatment mechanics and contemporary appliance design in orthodontics: a 40-year perspective. Am J Orthod Dentofacial Orthop. 147:654–62. DOI: 10.1016/j.ajodo.2015.03.012. PMID: 26038069.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Friction of calcium phosphate brackets to stainless steel wire

- Comparison of the frictional characteristics of aesthetic orthodontic brackets measured using a modified in vitro technique

- Frictional resistance of different ceramic brackets and their relationship to the second order angulation between bracket slot and wire

- A study on tensile strength and physical alteration of thermally recycled metal brackets

- A study on frictional resistance force of orthodontic resin bracket