J Adv Prosthodont.

2019 Aug;11(4):202-208. 10.4047/jap.2019.11.4.202.

Influence of heating rate on the flexural strength of monolithic zirconia

- Affiliations

-

- 1Department of Prosthodontics, Faculty of Dentistry, Hatay Mustafa Kemal University, Hatay, Turkey. caner_ozturk86@hotmail.com

- 2Department of Prosthodontics, Faculty of Dentistry, Ordu University, Ordu, Turkey.

- KMID: 2455928

- DOI: http://doi.org/10.4047/jap.2019.11.4.202

Abstract

- PURPOSE

Fabrication of zirconia restorations with ideal mechanical properties in a short period is a great challenge for clinicians. The purpose of the study was to investigate the effect of heating rate on the mechanical and microstructural properties of monolithic zirconia.

MATERIALS AND METHODS

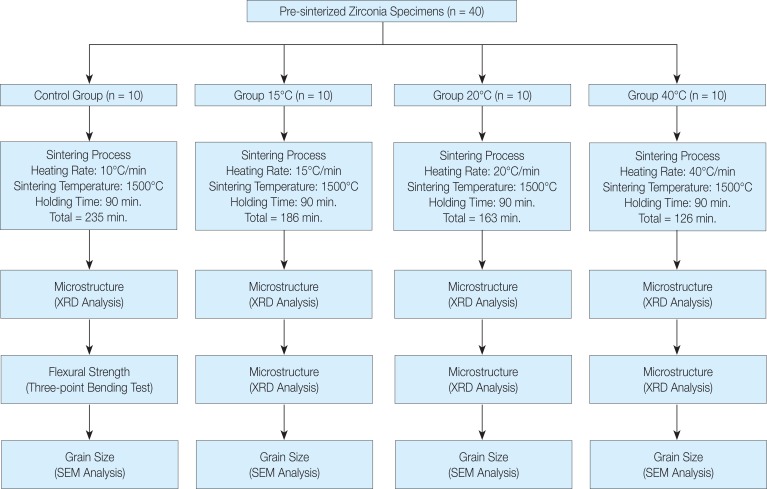

Forty monolithic zirconia specimens were prepared from presintered monolithic zirconia blanks. All specimens were then assigned to 4 groups according to heating rate as Control, Group 15℃, Group 20℃, and Group 40℃. All groups were sintered according to heating rates with the sintering temperature of 1500℃, a holding time of 90 minutes and natural cooling. The phase composition was examined by XRD analysis, three-point bending test was conducted to examine the flexural strength, and Weibull analysis was conducted to determine weibull modulus and characteristic strength. Average grain sizes were determined by SEM analysis. One-way ANOVA test was performed at a significance level of 0.05.

RESULTS

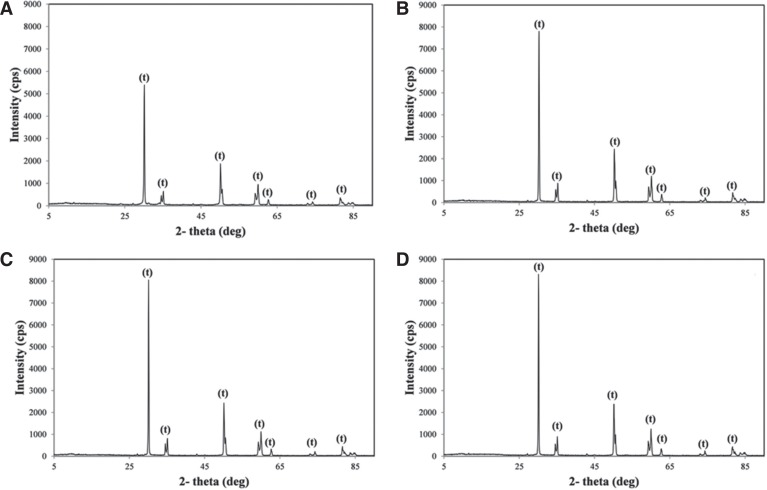

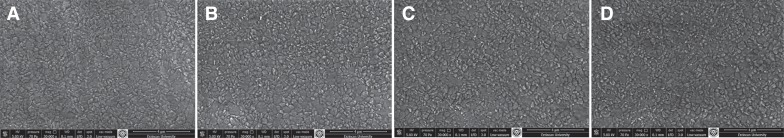

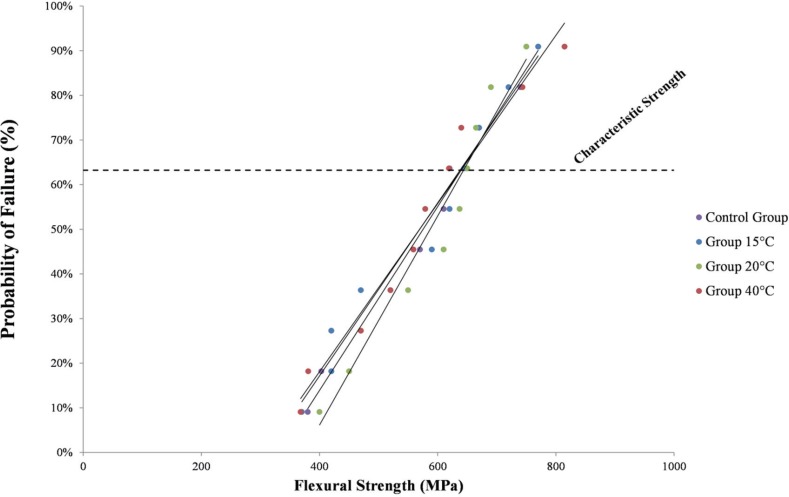

Only tetragonal phase characteristic peaks were determined on the surface of analyzed specimens. Differences among the average grain sizes of the groups were not statistically significant. The results of the three-point bending test revealed no significant differences among the flexural strength of the groups (P>.05). Weibull modulus of groups was ranging from 3.50 to 4.74. The highest and the lowest characteristic strength values were obtained in Group 20℃ and Control Group, respectively.

CONCLUSION

Heating rate has no significant effect on the flexural strength of monolithic zirconia. Monolithic zirconia restorations can be produced in shorter sintering periods without affecting the flexural strength by modifying the heating rate.

MeSH Terms

Figure

Cited by 1 articles

-

The effects of repetitive firing processes on the optical, thermal, and phase formation changes of zirconia

Alper Ozdogan, Hatice Ozdemir

J Adv Prosthodont. 2020;12(1):9-14. doi: 10.4047/jap.2020.12.1.9.

Reference

-

1. Kim HK, Kim SH. Effect of the number of coloring liquid applications on the optical properties of monolithic zirconia. Dent Mater. 2014; 30:e229–e237. PMID: 24853434.

Article2. Choi YS, Kim SH, Lee JB, Han JS, Yeo IS. In vitro evaluation of fracture strength of zirconia restoration veneered with various ceramic materials. J Adv Prosthodont. 2012; 4:162–169. PMID: 22977725.3. Triwatana P, Nagaviroj N, Tulapornchai C. Clinical performance and failures of zirconia-based fixed partial dentures: a review literature. J Adv Prosthodont. 2012; 4:76–83. PMID: 22737311.

Article4. Stawarczyk B, Ozcan M, Hallmann L, Ender A, Mehl A, Hämmerlet CH. The effect of zirconia sintering temperature on flexural strength, grain size, and contrast ratio. Clin Oral Investig. 2013; 17:269–274.

Article5. Lughi V, Sergo V. Low temperature degradation -aging- of zirconia: A critical review of the relevant aspects in dentistry. Dent Mater. 2010; 26:807–820. PMID: 20537701.

Article6. Piconi C, Maccauro G. Zirconia as a ceramic biomaterial. Biomaterials. 1999; 20:1–25. PMID: 9916767.

Article7. Studart AR, Filser F, Kocher P, Gauckler LJ. Fatigue of zirconia under cyclic loading in water and its implications for the design of dental bridges. Dent Mater. 2007; 23:106–114. PMID: 16473402.

Article8. Steffen AA, Dauskardt R, Ritchie R. Cyclic fatigue life and crack-growth behavior of microstructurally small cracks in magnesia-partially stabilized zirconia ceramics. J Am Ceram Soc. 1991; 74:1259–1268.9. Papia E, Jimbo R, Chrcanovic BR, Andersson M, Vult von Steyern P. Surface structure and mechanical properties of impaction-modified Y-TZP. Dent Mater. 2014; 30:808–816. PMID: 24962988.

Article10. Guazzato M, Quach L, Albakry M, Swain MV. Influence of surface and heat treatments on the flexural strength of Y-TZP dental ceramic. J Dent. 2005; 33:9–18. PMID: 15652163.

Article11. Ersoy NM, Aydoğdu HM, Değirmenci BÜ, Çökük N, Sevimay M. The effects of sintering temperature and duration on the flexural strength and grain size of zirconia. Acta Biomater Odontol Scand. 2015; 1:43–50. PMID: 28642900.

Article12. Kosmac T, Oblak C, Jevnikar P, Funduk N, Marion L. The effect of surface grinding and sandblasting on flexural strength and reliability of Y-TZP zirconia ceramic. Dent Mater. 1999; 15:426–433. PMID: 10863444.13. Swab JJ. Low temperature degradation of Y-TZP materials. J Mater Sci. 1991; 26:6706–6714.

Article14. Hjerppe J, Vallittu PK, Fröberg K, Lassila LV. Effect of sintering time on biaxial strength of zirconium dioxide. Dent Mater. 2009; 25:166–171. PMID: 18632146.

Article15. Hallmann L, Ulmer P, Reusser E, Louvel M, Hämmerlea CHF. Effect of dopants and sintering temperature on microstructure and low temperature degradation of dental Y-TZP-zirconia. J Eur Ceram Soc. 2012; 32:4091–4104.

Article16. Guess PC, Att W, Strub JR. Zirconia in fixed implant prosthodontics. Clin Implant Dent Relat Res. 2012; 14:633–645. PMID: 21176095.

Article17. Chevalier J. What future for zirconia as a biomaterial? Biomaterials. 2006; 27:535–543. PMID: 16143387.

Article18. Kaizer MR, Gierthmuehlen PC, Dos Santos MB, Cava SS, Zhang Y. Speed sintering translucent zirconia for chairside one-visit dental restorations: Optical, mechanical, and wear characteristics. Ceram Int. 2017; 43:10999–11005. PMID: 29097830.

Article19. Kim MJ, Ahn JS, Kim JH, Kim HY, Kim WC. Effects of the sintering conditions of dental zirconia ceramics on the grain size and translucency. J Adv Prosthodont. 2013; 5:161–166. PMID: 23755342.

Article20. Hjerppe J, Närhi T, Fröberg K, Vallittu PK, Lassila LV. Effect of shading the zirconia framework on biaxial strength and surface microhardness. Acta Odontol Scand. 2008; 66:262–267. PMID: 18645687.

Article21. Jiang L, Liao Y, Wan Q, Li W. Effects of sintering temperature and particle size on the translucency of zirconium dioxide dental ceramic. J Mater Sci Mater Med. 2011; 22:2429–2435. PMID: 21922331.

Article22. Ebeid K, Wille S, Hamdy A, Salah T, El-Etreby A, Kern M. Effect of changes in sintering parameters on monolithic translucent zirconia. Dent Mater. 2014; 30:e419–e424. PMID: 25262211.

Article23. ISO 6872. Dentistry-ceramic materials. Geneva; Switzerland: International Standards Organization (ISO);2015. Available at: https://www.iso.org/standard/74247.html.24. Guazzato M, Albakry M, Ringer SP, Swain MV. Strength, fracture toughness and microstructure of a selection of all-ceramic materials. Part II. Zirconia-based dental ceramics. Dent Mater. 2004; 20:449–456. PMID: 15081551.

Article25. Stawarczyk B, Frevert K, Ender A, Roos M, Sener B, Wimmer T. Comparison of four monolithic zirconia materials with conventional ones: Contrast ratio, grain size, four-point flexural strength and two-body wear. J Mech Behav Biomed Mater. 2016; 59:128–138. PMID: 26751707.

Article26. Kosmac T, Oblak C, Jevnikar P, Funduk N, Marion L. The effect of surface grinding and sandblasting on flexural strength and reliability of Y-TZP zirconia ceramic. Dent Mater. 1999; 15:426–433. PMID: 10863444.27. Denry I, Kelly JR. State of the art of zirconia for dental applications. Dent Mater. 2008; 24:299–307. PMID: 17659331.

Article28. Gupta TK, Lange FF, Bechtold JH. Effect of stress-induced phase transformation on the properties of polycrystalline zirconia containing metastable tetragonal phase. J Mater Sci. 1978; 13:1464–1470.

Article29. Kelly JR, Denry I. Stabilized zirconia as a structural ceramic: an overview. Dent Mater. 2008; 24:289–298. PMID: 17624420.

Article30. Bravo-Leon A, Morikawa Y, Kawahara M, Mayo MJ. Fracture toughness of nanocrystalline tetragonal zirconia with low yttria content. Acta Mater. 2002; 50:4555–4562.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Effect of coloring liquids on biaxial flexural strength of monolithic zirconia

- Esthetic anterior restoration using 3M Lavaâ„¢ Esthetic monolithic zirconia

- Effect of different coloring liquids on the flexural strength of multilayered zirconia

- Flexural strength and reliability of highly translucent colored zirconia

- Effect of sintering programs and surface treatments on monolithic zirconia