J Adv Prosthodont.

2018 Dec;10(6):408-414. 10.4047/jap.2018.10.6.408.

Effect of non-thermal plasma on the shear bond strength of resin cements to Polyetherketoneketone (PEKK)

- Affiliations

-

- 1Department of Prosthodontics, Institute for Clinical Dental Research, Korea University Medical Center, Seoul, Republic of Korea. wddc@korea.ac.kr

- KMID: 2429373

- DOI: http://doi.org/10.4047/jap.2018.10.6.408

Abstract

- PURPOSE

This study aimed to assess the effect of non-thermal plasma on the shear bond strength of resin cements to polyetherketoneketone (PEKK) in comparison to other surface treatment methods.

MATERIALS AND METHODS

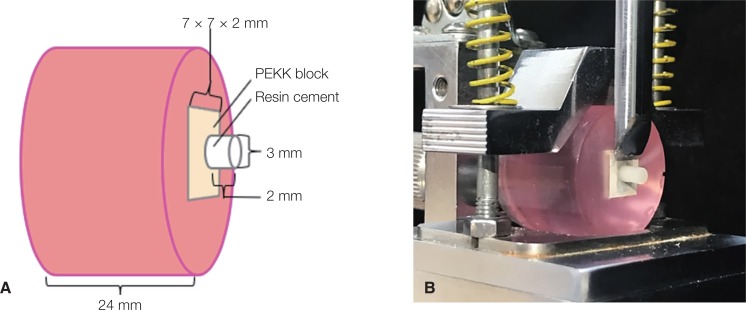

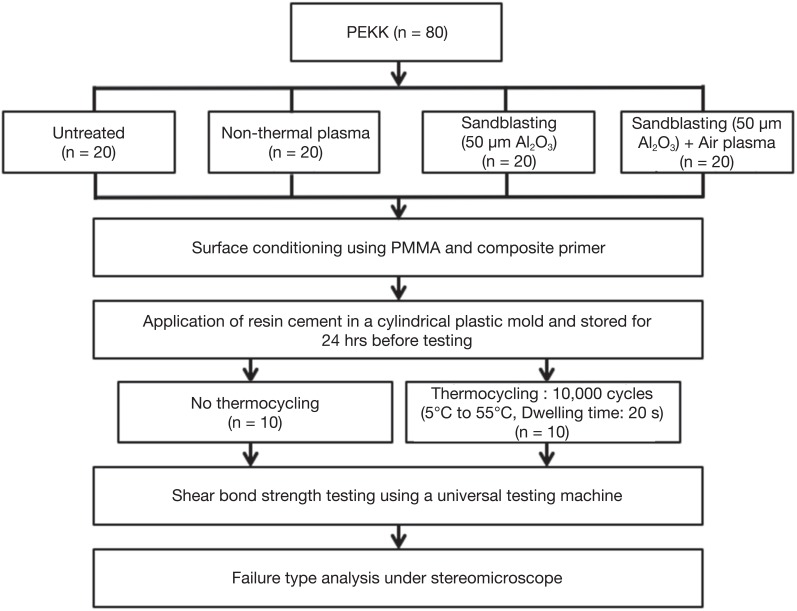

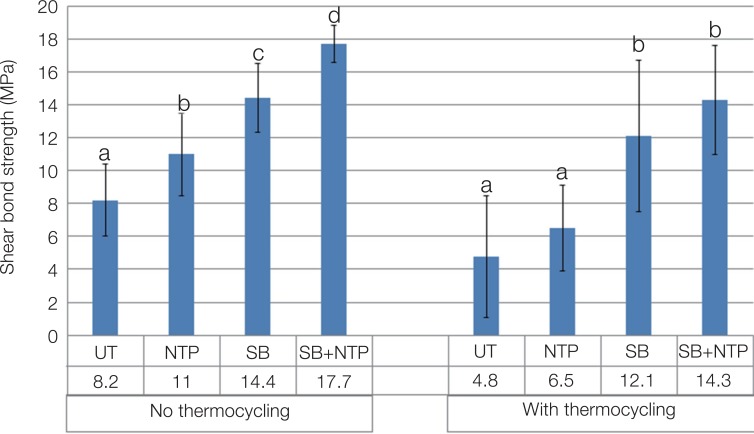

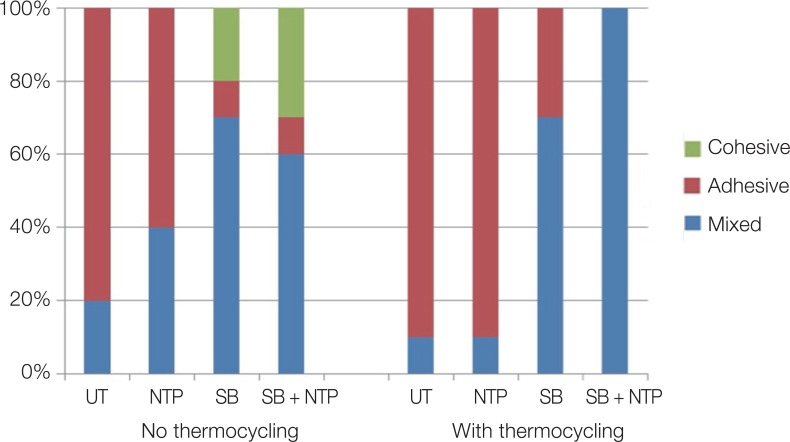

Eighty PEKK discs were subjected to different surface treatments: (1) Untreated (UT); (2) Non-thermal plasma (NTP); (3) Sandblasting with 50 µm Al2O3 particles (SB); and (4) Sandblasting + Non-thermal plasma (SB+NTP). After each surface treatment, the contact angle was measured. Surface conditioning with Visio.Link was applied in all groups after pre-treatment. RelyX Unicem resin cement was bonded onto the PEKK specimens. After fabrication of the specimens, half of each group (n=10) was initially tested, while the other half was subjected to thermocycling (5℃ to 55℃ at 10,000 cycles). Shear bond strength (SBS) testing was performed using a universal testing machine, and failure modes were assessed using stereomicroscopy. The SBS results were analyzed statistically using one-way ANOVA followed by Tukey's post hoc test. Independent t-test was used to examine the effect of thermocycling (P < .05).

RESULTS

The highest SBS values with or without thermocycling were observed with PEKK specimens that were treated with SB+NTP followed by the SB group. The lowest SBS results were observed in the UT groups.

CONCLUSION

The shear bond strength between PEKK and resin cements was improved using non-thermal plasma treatment in combination with sandblasting.

Keyword

MeSH Terms

Figure

Reference

-

1. Domininghaus H. Resin material and its properties, 6. Berlin, Heidelberg: Springer-Verlag;2005. p. 1203–1222.2. Mark H. Encyclopedia of polymer science and technology, 3. Hoboken, NJ: John Wiley & Sons;2007. p. 377.3. Kurtz SM, Devine JN. PEEK biomaterials in trauma, orthopedic, and spinal implants. Biomaterials. 2007; 28:4845–4869. PMID: 17686513.

Article4. Toth JM, Wang M, Ester BT, Scifert JL, Seim HB, Turner HS. Polyetheretherketone as a biomaterial for spinal applications. Biomaterials. 2006; 27:324–334. PMID: 16115677.

Article5. Fuhrmann G, Steiner M, Freitag-Wolf S, Kern M. Resin bonding to three types of polyaryletherketones (PAEKs)-durability and influence of surface conditioning. Dent Mater. 2014; 30:357–363. PMID: 24461250.

Article6. Han KH, Lee JY, Shin SW. Implant- and Tooth-Supported Fixed Prostheses Using a High-Performance Polymer (Pekkton) Framework. Int J Prosthodont. 2016; 29:451–454. PMID: 27611747.

Article7. Lee KS, Shin JH, Kim JE, Kim JH, Lee WC, Shin SW, Lee JY. Biomechanical Evaluation of a Tooth Restored with High Performance Polymer PEKK Post-Core System: A 3D Finite Element Analysis. Biomed Res Int. 2017; 2017:1373127. PMID: 28386547.

Article8. Stawarczyk B, Keul C, Beuer F, Roos M, Schmidlin PR. Tensile bond strength of veneering resins to PEEK: impact of different adhesives. Dent Mater J. 2013; 32:441–448. PMID: 23719006.

Article9. Zhou L, Qian Y, Zhu Y, Liu H, Gan K, Guo J. The effect of different surface treatments on the bond strength of PEEK composite materials. Dent Mater. 2014; 30:e209–e215. PMID: 24768752.

Article10. Noiset O, Schneider YJ, Marchand-Brynaert J. Adhesion and growth of CaCo2 cells on surface-modified PEEK substrata. J Biomater Sci Polym Ed. 2000; 11:767–786. PMID: 11011772.

Article11. Chen M, Zhang Y, Sky Driver M, Caruso AN, Yu Q, Wang Y. Surface modification of several dental substrates by non-thermal, atmospheric plasma brush. Dent Mater. 2013; 29:871–880. PMID: 23755823.

Article12. Rodriguez-Villanueva C, Encinas N, Abenojar J, Martinez MA. Assessment of atmospheric plasma treatment cleaning effect on steel surfaces. Surf Coat Technol. 2013; 236:450–456.13. Comyn J, Mascia L, Xiao G, Parker BM. Plasma-treatment of polyetheretherketone (PEEK) for adhesive bonding. Int J Adhes Adhes. 1996; 16:97–104.

Article14. Schmidlin PR, Stawarczyk B, Wieland M, Attin T, Hämmerle CH, Fischer J. Effect of different surface pre-treatments and luting materials on shear bond strength to PEEK. Dent Mater. 2010; 26:553–559. PMID: 20206986.

Article15. Stawarczyk B, Jordan P, Schmidlin PR, Roos M, Eichberger M, Gernet W, Keul C. PEEK surface treatment effects on tensile bond strength to veneering resins. J Prosthet Dent. 2014; 112:1278–1288. PMID: 24969411.

Article16. Stawarczyk B, Beuer F, Wimmer T, Jahn D, Sener B, Roos M, Schmidlin PR. Polyetheretherketone-a suitable material for fixed dental prostheses? J Biomed Mater Res B Appl Biomater. 2013; 101:1209–1216. PMID: 23564476.

Article17. Sproesser O, Schmidlin PR, Uhrenbacher J, Roos M, Gernet W, Stawarczyk B. Effect of sulfuric acid etching of polyetheretherketone on the shear bond strength to resin cements. J Adhes Dent. 2014; 16:465–472. PMID: 25264546.18. Hallmann L, Mehl A, Sereno N, Hammerle C. The improvement of adhesive properties of PEEK through pre-treatments. Appl Surf Sci. 2012; 258:7213–7218.19. Pourkhalili H, Dastjerdi MR, Soltankarimi V, Razavi AS, Ramezani A, Talari FS, Alhavaz A. Effect of different surface treatment on the shear bond strength of veneering composite to polyetherketone core material. Int J Adv Biotech Res. 2016; 7:1116–1121.20. Kern M, Lehmann F. Influence of surface conditioning on bonding to polyetheretherketon (PEEK). Dent Mater. 2012; 28:1280–1283. PMID: 23036863.

Article21. Keul C, Liebermann A, Schmidlin PR, Roos M, Sener B, Stawarczyk B. Influence of PEEK surface modification on surface properties and bond strength to veneering resin composites. J Adhes Dent. 2014; 16:383–392. PMID: 25133270.22. Stawarczyk B, Taufall S, Roos M, Schmidlin PR, Lümkemann N. Bonding of composite resins to PEEK: the influence of adhesive systems and air-abrasion parameters. Clin Oral Investig. 2018; 22:763–771.

Article23. Yavirach P, Chaijareenont P, Boonyawan D, Pattamapun K, Tunma S, Takahashi H, Arksornnukit M. Effects of plasma treatment on the shear bond strength between fiber-reinforced composite posts and resin composite for core build-up. Dent Mater J. 2009; 28:686–692. PMID: 20019419.

Article24. Stawarczyk B, Bähr N, Beuer F, Wimmer T, Eichberger M, Gernet W, Jahn D, Schmidlin PR. Influence of plasma pretreatment on shear bond strength of self-adhesive resin cements to polyetheretherketone. Clin Oral Investig. 2014; 18:163–170.

Article25. Pelagade S, Singh NL, Shah S, Qureshi A, Rane RS, Mukherjee S, Deshpande UP, Ganesan V, Shripathi T. Surface free energy analysis for bipolar pulsed argon plasma treated polymer films. J Phys. 2010; 208:012107.

Article26. Kim S, Lee KJ, Seo Y. Polyetheretherketone (PEEK) surface functionalization by low-energy ion-beam irradiation under a reactive O2 environment and its effect on the PEEK/copper adhesives. Langmuir. 2004; 20:157–163. PMID: 15745014.

Article27. Stawarczyk B, Silla M, Roos M, Eichberger M, Lümkemann N. Bonding behaviour of polyetherketoneketone to methylmethacrylate-and dimethacrylate-based polymers. J Adhes Dent. 2017; 19:331–338. PMID: 28849801.28. Piwowarczyk A, Lauer HC, Sorensen JA. In vitro shear bond strength of cementing agents to fixed prosthodontic restorative materials. J Prosthet Dent. 2004; 92:265–273. PMID: 15343162.

Article29. Nair K, Whiteside B, Grant C, Patel R, Tuinea-Bobe C, Norris K, Paradkar A. Investigation of plasma treatment on micro-injection moulded microneedle for drug delivery. Pharmaceutics. 2015; 7:471–485. PMID: 26529005.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- A study of the tensile bond strength between Polyetherketoneketone (PEKK) and various veneered denture base resin

- A study on the shear bond strength between 3D printed resin and provisional resin after thermal cycling

- Effect Of Dentin Desensitizers On Shear Bond Strength Of Resin Cements

- The effect of repeated bonding on the shear bond strength of different resin cements to enamel and dentin

- THE EFFECTS OF THERMAL CYCLING ON THE BOND STRENGTH OF SELF-CURING RESIN