J Adv Prosthodont.

2018 Aug;10(4):321-327. 10.4047/jap.2018.10.4.321.

A study on the machining accuracy of dental digital method focusing on dental inlay

- Affiliations

-

- 1Department of Dental Laboratory Science and Engineering, College of Health Science, Korea University, Seoul, Republic of Korea. kjh2804@korea.ac.kr

- KMID: 2418639

- DOI: http://doi.org/10.4047/jap.2018.10.4.321

Abstract

- PURPOSE

The purpose of this study was to compare the cutting method and the lamination method to investigate whether the CAD data of the proposed inlay shape are machined correctly.

MATERIALS AND METHODS

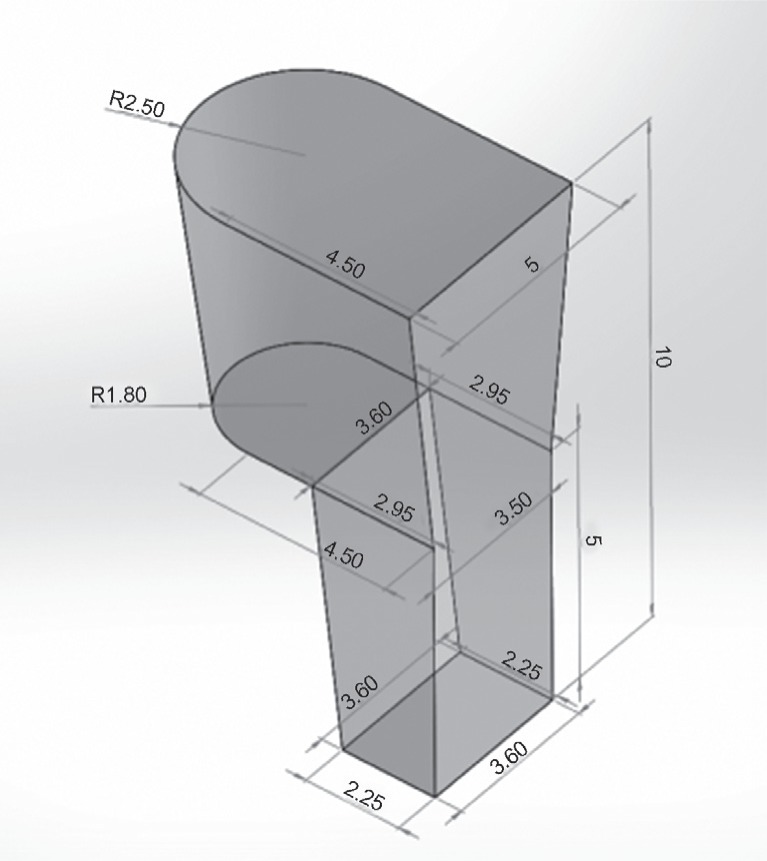

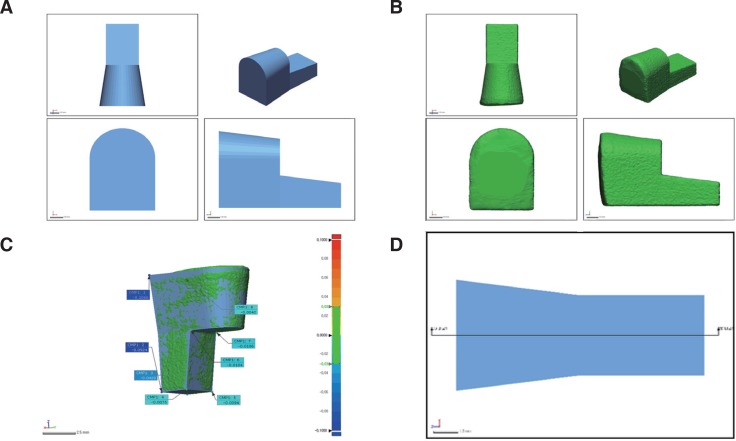

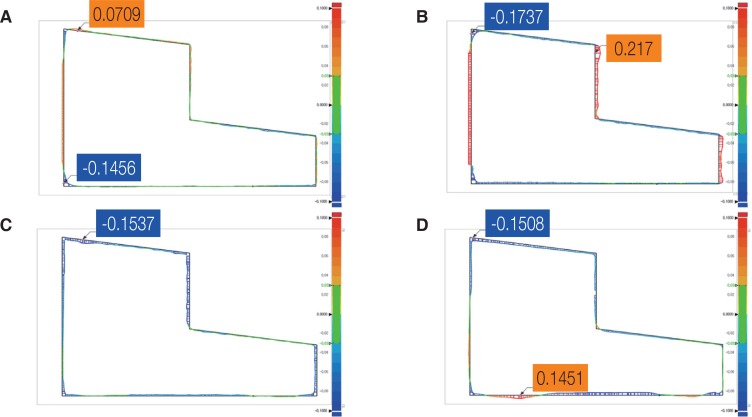

The Mesial-Occlusal shape of the inlay was modeled by changing the stereolithography (STL). Each group used SLS (metal powder) or SLA (photocurable resin) in the additive method, and wax or zirconia in the subtractive method (n=10 per group, total n=40). Three-dimensional (3D) analysis program (Geomagic Control X inspection software; 3D systems) was used for the alignment and analysis. The root mean square (RMS) in the 2D plane state was measured within 50 µm radius of eight comparison measuring points (CMP). Differences were analyzed using one-way analysis of variance and post-hoc Tukey's test were used (α=.05).

RESULTS

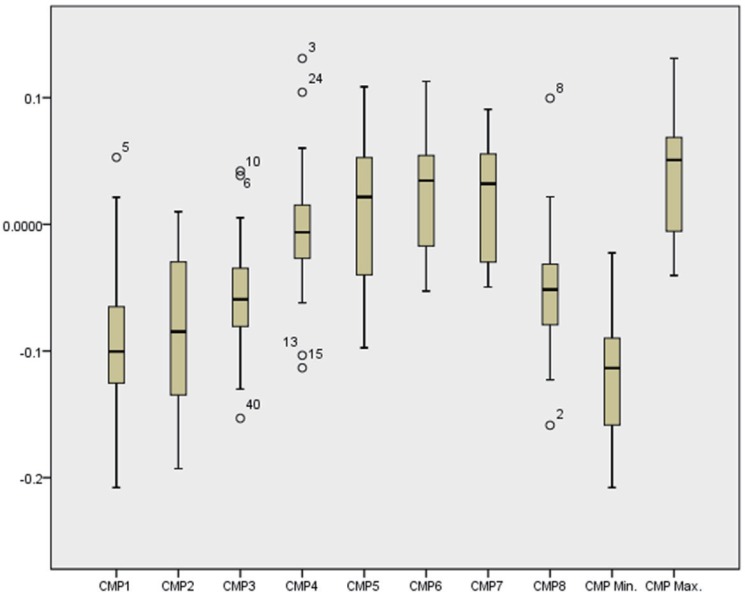

There was a significant difference in RMS only in SLA and SLS of 2D section (P < .05). In CMP mean, CMP 4 (−5.3±46.7 µm) had a value closest to 0, while CMP 6 (20.1±42.4 µm) and CMP 1 (−89.2±61.4 µm) had the greatest positive value and the greatest negative value, respectively.

CONCLUSION

Since the errors obtained from the study do not exceed the clinically acceptable values, the lamination method and the cutting method can be used clinically.

Figure

Reference

-

1. ISO/ASTM F2915. 2013 Standard specification for additive manufacturing file format (AMF) Version 1.1. Available from: https://www.astm.org/Standards/F2915.htm.2. ASTM. Additive Manufacturing File Format (AMF). 2017-07-25. Available from: http://amf.wikispaces.com/.3. Wimpenny DI, Pandey PM, Kumar LJ, editors. Advances in 3D printing & additive manufacturing technologies. Singapore: Springer;2017.4. Miyazaki T, Hotta Y. CAD/CAM systems available for the fabrication of crown and bridge restorations. Aust Dent J. 2011; 56(Suppl 1):97–106.

Article5. Traini T, Mangano C, Sammons RL, Mangano F, Macchi A, Piattelli A. Direct laser metal sintering as a new approach to fabrication of an isoelastic functionally graded material for manufacture of porous titanium dental implants. Dent Mater. 2008; 24:1525–1533. PMID: 18502498.

Article6. Venkatesh KV, Nandini VV. Direct metal laser sintering: a digitised metal casting technology. J Indian Prosthodont Soc. 2013; 13:389–392. PMID: 24431766.

Article7. Atieh MA, Ritter AV, Ko CC, Duqum I. Accuracy evaluation of intraoral optical impressions: A clinical study using a reference appliance. J Prosthet Dent. 2017; 118:400–405. PMID: 28222869.

Article8. Sykes LM, Parrott AM, Owen CP, Snaddon DR. Applications of rapid prototyping technology in maxillofacial prosthetics. Int J Prosthodont. 2004; 17:454–459. PMID: 15382782.9. Currier JH. A computerized geometric analysis of human dental arch form. Am J Orthod. 1969; 56:164–179. PMID: 4896226.

Article10. Marghalani TY. Frequency of undercuts and favorable path of insertion in abutments prepared for fixed dental prostheses by preclinical dental students. J Prosthet Dent. 2016; 116:564–569. PMID: 27174407.

Article11. Dawood A, Marti Marti B, Sauret-Jackson V, Darwood A. 3D printing in dentistry. Br Dent J. 2015; 219:521–529. PMID: 26657435.

Article12. Witkowski S, Komine F, Gerds T. Marginal accuracy of titanium copings fabricated by casting and CAD/CAM techniques. J Prosthet Dent. 2006; 96:47–52. PMID: 16872930.

Article13. Castillo-de-Oyagüe R, Sánchez-Turrión A, López-Lozano JF, Albaladejo A, Torres-Lagares D, Montero J, Suárez-García MJ. Vertical misfit of laser-sintered and vacuum-cast implant-supported crown copings luted with definitive and temporary luting agents. Med Oral Patol Oral Cir Bucal. 2012; 17:e610–e617. PMID: 22322524.14. Abou Tara M, Eschbach S, Bohlsen F, Kern M. Clinical outcome of metal-ceramic crowns fabricated with laser-sintering technology. Int J Prosthodont. 2011; 24:46–48. PMID: 21210003.15. Bae EJ, Kim JH, Kim WC, Kim HY. Bond and fracture strength of metal-ceramic restorations formed by selective laser sintering. J Adv Prosthodont. 2014; 6:266–271. PMID: 25177469.

Article16. Kim KB, Kim WC, Kim HY, Kim JH. An evaluation of marginal fit of three-unit fixed dental prostheses fabricated by direct metal laser sintering system. Dent Mater. 2013; 29:e91–e96. PMID: 23680302.

Article17. Ucar Y, Akova T, Akyil MS, Brantley WA. Internal fit evaluation of crowns prepared using a new dental crown fabrication technique: laser-sintered Co-Cr crowns. J Prosthet Dent. 2009; 102:253–259. PMID: 19782828.

Article18. Xin XZ, Chen J, Xiang N, Wei B. Surface properties and corrosion behavior of Co-Cr alloy fabricated with selective laser melting technique. Cell Biochem Biophys. 2013; 67:983–990. PMID: 23553145.

Article19. He HY, Zhang JY, Mi X, Hu Y, Gu XY. Rapid prototyping for tissue-engineered bone scaffold by 3D printing and biocompatibility study. Int J Clin Exp Med. 2015; 8:11777–11785. PMID: 26380018.20. ISO. 12836:2015 Dentistry - Digitizing devices for CAD/CAM systems for indirect dental restorations - Test methods for assessing accuracy. Geneva; Switzerland: International Organization for Standardization;2012.21. Koch GK, Gallucci GO, Lee SJ. Accuracy in the digital workflow: From data acquisition to the digitally milled cast. J Prosthet Dent. 2016; 115:749–754. PMID: 26803173.

Article22. Brodkin D, Panzera C, Panzera P. U.S. Patent No. 6,322,728. Washington, DC: U.S. Patent and Trademark Office;2001.23. Bosch G, Ender A, Mehl A. A 3-dimensional accuracy analysis of chairside CAD/CAM milling processes. J Prosthet Dent. 2014; 112:1425–1431. PMID: 24993373.

Article24. Bae EJ, Jeong ID, Kim WC, Kim JH. A comparative study of additive and subtractive manufacturing for dental restorations. J Prosthet Dent. 2017; 118:187–193. PMID: 28089336.

Article25. McMains S. Layered manufacturing technologies. Commun ACM. 2005; 48:50–56.

Article26. Mandal N, Doloi B, Mondal B. Development of flank wear prediction model of Zirconia Toughened Alumina (ZTA) cutting tool using response surface methodology. Int J Refract Metals Hard Mater. 2011; 29:273–280.

Article27. Gu D, Shen Y. Balling phenomena in direct laser sintering of stainless steel powder: Metallurgical mechanisms and control methods. Mater Des. 2009; 30:2903–2910.

Article28. Li R, Liu J, Shi Y, Wang L, Jiang W. Balling behavior of stainless steel and nickel powder during selective laser melting process. Int J Adv Manuf Technol. 2012; 59:1025–1035.

Article29. Abou Tara M, Eschbach S, Wolfart S, Kern M. Zirconia ceramic inlay-retained fixed dental prostheses - first clinical results with a new design. J Dent. 2011; 39:208–211. PMID: 21185905.

Article30. Kohorst P, Brinkmann H, Li J, Borchers L, Stiesch M. Marginal accuracy of four-unit zirconia fixed dental prostheses fabricated using different computer-aided design/computer-aided manufacturing systems. Eur J Oral Sci. 2009; 117:319–325. PMID: 19583762.

Article31. Reich S, Wichmann M, Nkenke E, Proeschel P. Clinical fit of all-ceramic three-unit fixed partial dentures, generated with three different CAD/CAM systems. Eur J Oral Sci. 2005; 113:174–179. PMID: 15819826.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Evaluation of the machinability and machining accuracy of dental CAD/CAM wax blocks using merlon fracture test model

- A review on the accuracy assessment methods of 3-dimensional digital dental models

- Clinical Validity of Tooth Size Measurements Obtained via Digital Methods with Intraoral Scanning

- Comparison of digital models generated from three-dimensional optical scanner and cone beam computed tomography

- Image fusion accuracy for the integration of digital dental model and 3D CT images by the point-based surface best fit algorithm