J Adv Prosthodont.

2016 Feb;8(1):62-69. 10.4047/jap.2016.8.1.62.

Effect of abutment screw length and cyclic loading on removal torque in external and internal hex implants

- Affiliations

-

- 1Department of Prosthodontics, College of Dentistry, Wonkwang University, Iksan, Republic of Korea. hwcho@wku.ac.kr

- 2Department of Dental Biomaterials, College of Dentistry, Wonkwang University, Iksan, Republic of Korea.

- KMID: 2393197

- DOI: http://doi.org/10.4047/jap.2016.8.1.62

Abstract

- PURPOSE

The purpose of this study was to evaluate the effects of abutment screw length and cyclic loading on the removal torque (RTV) in external hex (EH) and internal hex (IH) implants.

MATERIALS AND METHODS

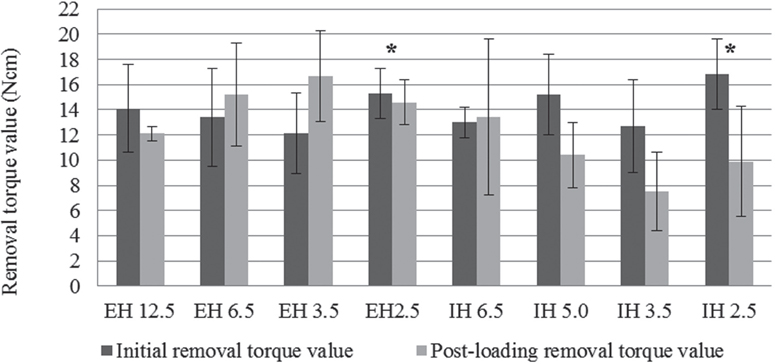

Forty screw-retained single crowns were connected to external and internal hex implants. The prepared titanium abutment screws were classified into 8 groups based on the number of threads (n = 5 per group): EH 12.5, 6.5, 3.5, 2.5 and IH 6.5, 5, 3.5, 2.5 threads. The abutment screws were tightened with 20 Ncm torque twice with 10-minute intervals. After 5 minutes, the initial RTVs of the abutment screws were measured with a digital torque gauge (MGT12). A customized jig was constructed to apply a load along the implant long axis at the central fossa of the maxillary first molar. The post-loading RTVs were measured after 16,000 cycles of mechanical loading with 50 N at a 1-Hz frequency. Statistical analysis included one-way analysis of variance and paired t-tests.

RESULTS

The post-loading RTVs were significantly lower than the initial RTVs in the EH 2.5 thread and IH 2.5 thread groups (P<.05). The initial RTVs exhibited no significant differences among the 8 groups, whereas the post-loading RTVs of the EH 6.5 and EH 3.5 thread groups were higher than those of the IH 3.5 thread group (P<.05).

CONCLUSION

Within the limitations of this study, the external hex implants with short screw lengths were more advantageous than internal hex implants with short screw lengths in torque maintenance after cyclic loading.

Keyword

Figure

Cited by 1 articles

-

Screw loosening and changes in removal torque relative to abutment screw length in a dental implant with external abutment connection after oblique cyclic loading

Joo-Hee Lee, Hyun-Suk Cha

J Adv Prosthodont. 2018;10(6):415-421. doi: 10.4047/jap.2018.10.6.415.

Reference

-

1. Cibirka RM, Nelson SK, Lang BR, Rueggeberg FA. Examination of the implant-abutment interface after fatigue testing. J Prosthet Dent. 2001; 85:268–275.2. Jörnéus L, Jemt T, Carlsson L. Loads and designs of screw joints for single crowns supported by osseointegrated implants. Int J Oral Maxillofac Implants. 1992; 7:353–359.3. Bianco G, Di Raimondo R, Luongo G, Paoleschi C, Piccoli P, Piccoli C, Rangert B. Osseointegrated implant for single tooth replacement: A retrospective multicenter study on routine use in private practice. Clin Implant Dent Relat Res. 2000; 2:152–158.4. Theoharidou A, Petridis HP, Tzannas K, Garefis P. Abutment screw loosening in single-implant restorations: a systematic review. Int J Oral Maxillofac Implants. 2008; 23:681–690.5. Richter EJ. In vivo horizontal bending moments on implants. Int J Oral Maxillofac Implants. 1998; 13:232–244.6. Bickford JH. An introduction to the design and behavior of bolted joints. New York: Marcel Dekker;1995. p. 515–564.7. Tsuge T, Hagiwara Y. Influence of lateral-oblique cyclic loading on abutment screw loosening of internal and external hexagon implants. Dent Mater J. 2009; 28:373–381.8. Delben JA, Gomes EA, Barão VA, Assunção WG. Evaluation of the effect of retightening and mechanical cycling on preload maintenance of retention screws. Int J Oral Maxillofac Implants. 2011; 26:251–256.9. Stüker RA, Teixeira ER, Beck JC, da Costa NP. Preload and torque removal evaluation of three different abutment screws for single standing implant restorations. J Appl Oral Sci. 2008; 16:55–58.10. Khraisat A, Hashimoto A, Nomura S, Miyakawa O. Effect of lateral cyclic loading on abutment screw loosening of an external hexagon implant system. J Prosthet Dent. 2004; 91:326–334.11. Shigley JE. Mechanical engineering design. 3rd ed. New York: McGraw Hill;1977. p. 240–245.12. Weiss EI, Kozak D, Gross MD. Effect of repeated closures on opening torque values in seven abutment-implant systems. J Prosthet Dent. 2000; 84:194–199.13. Delben JA, Barão VA, Dos Santos PH, Assunção WG. Influence of abutment type and esthetic veneering on preload maintenance of abutment screw of implant-supported crowns. J Prosthodont. 2014; 23:134–139.14. Khraisat A, Abu-Hammad O, Dar-Odeh N, Al-Kayed AM. Abutment screw loosening and bending resistance of external hexagon implant system after lateral cyclic loading. Clin Implant Dent Relat Res. 2004; 6:157–164.15. Al Jabbari YS, Fournelle R, Ziebert G, Toth J, Iacopino AM. Mechanical behavior and failure analysis of prosthetic retaining screws after long-term use in vivo. Part 1: Characterization of adhesive wear and structure of retaining screws. J Prosthodont. 2008; 17:168–180.16. Shin HM, Huh JB, Yun MJ, Jeon YC, Chang BM, Jeong CM. Influence of the implant-abutment connection design and diameter on the screw joint stability. J Adv Prosthodont. 2014; 6:126–132.17. Gracis S, Michalakis K, Vigolo P, Vult von Steyern P, Zwahlen M, Sailer I. Internal vs. external connections for abutments/reconstructions: A systematic review. Clin Oral Implants Res. 2012; 23:202–216.18. Feitosa PC, de Lima AP, Silva-Concílio LR, Brandt WC, Neves AC. Stability of external and internal implant connections after a fatigue test. Eur J Dent. 2013; 7:267–271.19. Kim KS, Han JS, Lim YJ. Settling of abutments into implants and changes in removal torque in five different implant-abutment connections. Part 1: Cyclic loading. Int J Oral Maxillofac Implants. 2014; 29:1079–1084.20. Binon PP. Implants and components: entering the new millennium. Int J Oral Maxillofac Implants. 2000; 15:76–94.21. Sopwith DG. The distribution of load in screw threads. Proc Inst Mech Eng. 1948; 159:373–383.22. Kim BJ, Yeo IS, Lee JH, Kim SK, Heo SJ, Koak JY. The effect of screw length on fracture load and abutment strain in dental implants with external abutment connections. Int J Oral Maxillofac Implants. 2012; 27:820–823.23. Choi JH, Yang JH, Cho WP, Lee JB. The influence of abutment screw length and repeated tightening on screw loosening in dental implant. J Korean Acad Prosthodont. 2006; 44:432–442.24. Yeo IS, Lee JH, Kang TJ, Kim SK, Heo SJ, Koak JY, Park JM, Lee SY. The effect of abutment screw length on screw loosening in dental implants with external abutment connections after thermocycling. Int J Oral Maxillofac Implants. 2014; 29:59–62.25. Park SD, Lee Y, Kim YL, Yu SH, Bae JM, Cho HW. Microleakage of different sealing materials in access holes of internal connection implant systems. J Prosthet Dent. 2012; 108:173–180.26. Winkler S, Ring K, Ring JD, Boberick KG. Implant screw mechanics and the settling effect: Overview. J Oral Implantol. 2003; 29:242–245.27. Graf H. Bruxism. Dent Clin North Am. 1969; 13:659–665.28. Haack JE, Sakaguchi RL, Sun T, Coffey JP. Elongation and preload stress in dental implant abutment screws. Int J Oral Maxillofac Implants. 1995; 10:529–536.29. Maeda Y, Satoh T, Sogo M. In vitro differences of stress concentrations for internal and external hex implant-abutment connections: a short communication. J Oral Rehabil. 2006; 33:75–78.30. Kim ES, Shin SY. Influence of the implant abutment types and the dynamic loading on initial screw loosening. J Adv Prosthodont. 2013; 5:21–28.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Screw loosening and changes in removal torque relative to abutment screw length in a dental implant with external abutment connection after oblique cyclic loading

- The assessment of abutment screw stability between the external and internal hexagonal joint under cyclic loading

- Comparison of removal torque between prefabricated and customized abutment screw

- Removal torque of a two-piece zirconia abutment with a novel titanium component in an internal connection implant system after dynamic cyclic loading

- Effect of cyclic loading and retightening on reverse torque value in external and internal implants