J Adv Prosthodont.

2016 Jun;8(3):219-223. 10.4047/jap.2016.8.3.219.

Creating a digitized database of maxillofacial prostheses (obturators): A pilot study

- Affiliations

-

- 1Tokyo Medical and Dental University - Maxillofacial Prosthetics, Buniyo-ku, Tokyo, Japan. sasamfp@tmd.ac.jp

- KMID: 2376847

- DOI: http://doi.org/10.4047/jap.2016.8.3.219

Abstract

- PURPOSE

This study aimed to create a digitized database of fabricated obturators to be kept for patients' potential emergency needs.

MATERIALS AND METHODS

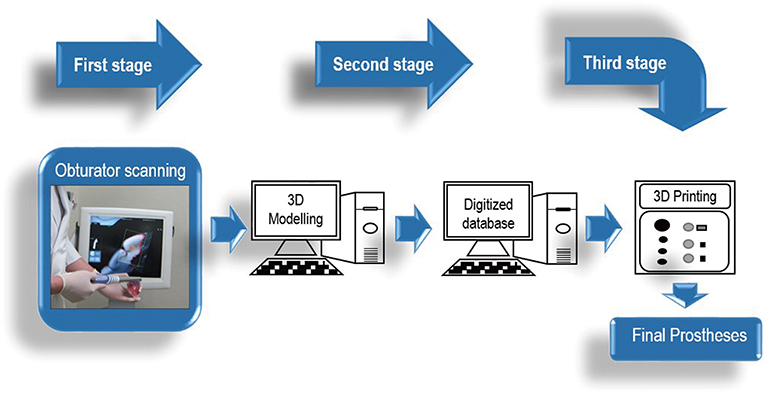

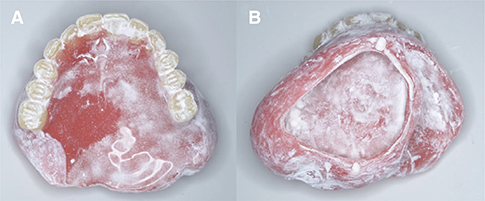

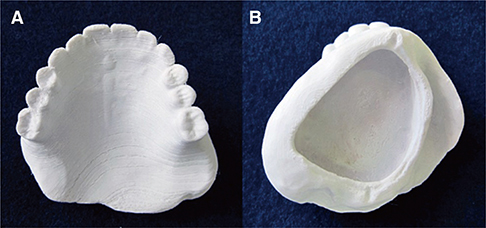

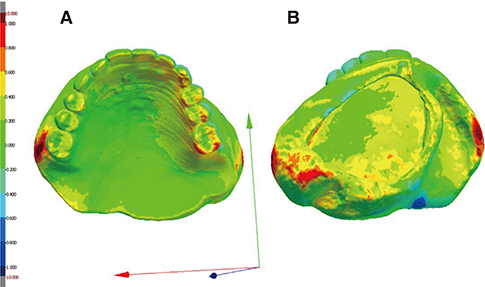

A chairside intraoral scanner was used to scan the surfaces of an acrylic resin obturator. The scanned data was recorded and saved as a single standard tessellation language file using a three-dimensional modeling software. A simulated obturator model was manufactured using fused deposition modeling technique in a three-dimensional printer.

RESULTS

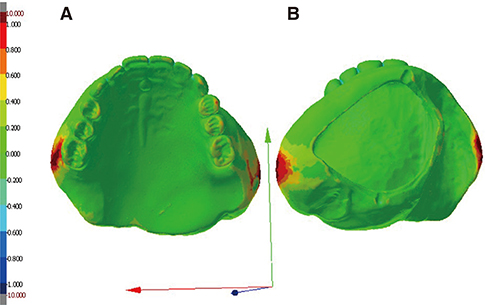

The entire obturator was successfully scanned regardless of its structural complexity, modeled as three-dimensional data, and stored in the digital system of our clinic at a relatively small size (19.6 MB). A simulated obturator model was then accurately manufactured from these data.

CONCLUSION

This study provides a proof-of-concept for the use of digital technology to create a digitized database of obturators for edentulous maxillectomy patients.

Figure

Reference

-

1. Elbashti ME, Hattori M, Sumita YI, Taniguchi H. Evaluation of articulation simulation system using artificial maxillectomy models. J Oral Rehabil. 2015; 42:678–684.2. Sumita YI, Ozawa S, Mukohyama H, Ueno T, Ohyama T, Taniguchi H. Digital acoustic analysis of five vowels in maxillectomy patients. J Oral Rehabil. 2002; 29:649–656.3. Kumar P, Alvi HA, Rao J, Singh BP, Jurel SK, Kumar L, Aggarwal H. Assessment of the quality of life in maxillectomy patients: A longitudinal study. J Adv Prosthodont. 2013; 5:29–35.4. van Noort R. The future of dental devices is digital. Dent Mater. 2012; 28:3–12.5. Syrek A, Reich G, Ranftl D, Klein C, Cerny B, Brodesser J. Clinical evaluation of all-ceramic crowns fabricated from intraoral digital impressions based on the principle of active wavefront sampling. J Dent. 2010; 38:553–559.6. Gibson I, Rosen D, Stucker B. Additive manufacturing technologies: 3D printing, rapid prototyping, and direct digital manufacturing. 2nd ed. New York: Springer;2014.7. Lethaus B, Lie N, de Beer F, Kessler P, de Baat C, Verdonck HW. Surgical and prosthetic reconsiderations in patients with maxillectomy. J Oral Rehabil. 2010; 37:138–142.8. Rimell JT, Marquis PM. Selective laser sintering of ultra high molecular weight polyethylene for clinical applications. J Biomed Mater Res. 2000; 53:414–420.9. Sabol JV, Grant GT, Liacouras P, Rouse S. Digital image capture and rapid prototyping of the maxillofacial defect. J Prosthodont. 2011; 20:310–314.10. Chen Y, Medioni G. Object modeling by registration of multiple range images. Image Vis Comput. 1992; 14:145–155.11. Luthardt RG, Loos R, Quaas S. Accuracy of intraoral data acquisition in comparison to the conventional impression. Int J Comput Dent. 2005; 8:283–294.12. Mehl A, Ender A, Mörmann W, Attin T. Accuracy testing of a new intraoral 3D camera. Int J Comput Dent. 2009; 12:11–28.13. Ender A, Mehl A. Full arch scans: conventional versus digital impressions-an in-vitro study. Int J Comput Dent. 2011; 14:11–21.14. van der Meer WJ, Andriessen FS, Wismeijer D, Ren Y. Application of intra-oral dental scanners in the digital workflow of implantology. PLoS One. 2012; 7:e43312.15. Sykes LM, Parrott AM, Owen CP, Snaddon DR. Applications of rapid prototyping technology in maxillofacial prosthetics. Int J Prosthodont. 2004; 17:454–459.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Patients' satisfaction on the obturators with different extension heights into defects after maxillectomy

- Application of 3D printing technology for rehabilitating maxillary defects

- Clinical Study of Maxillofacial Prostheses (Osseointegrated Implants for Maxillofacial Prostheses)

- The Presence of Yeast-like Fungi on Maxillary Prostheses with Obturators and in Post Surgical Cavities in Patients Operated on for Maxillary Neoplasms

- Errors in digitized lateral cephalometric radiography