J Adv Prosthodont.

2014 Feb;6(1):39-45. 10.4047/jap.2014.6.1.39.

Three-dimensional accuracy of different correction methods for cast implant bars

- Affiliations

-

- 1Department of Prosthodontics and Dental Research Institute, School of Dentistry, Seoul National University, Seoul, Republic of Korea. silk1@snu.ac.kr

- KMID: 2176569

- DOI: http://doi.org/10.4047/jap.2014.6.1.39

Abstract

- PURPOSE

The aim of the present study was to evaluate the accuracy of three techniques for correction of cast implant bars.

MATERIALS AND METHODS

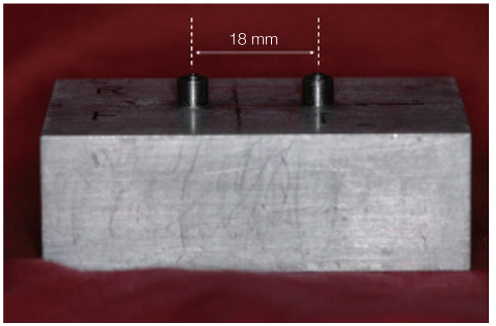

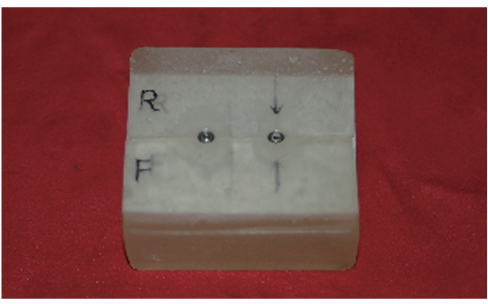

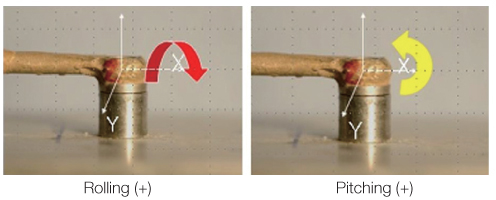

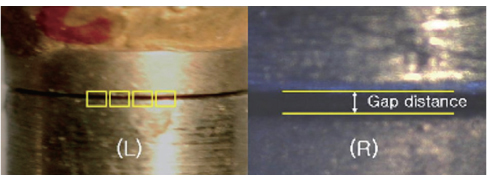

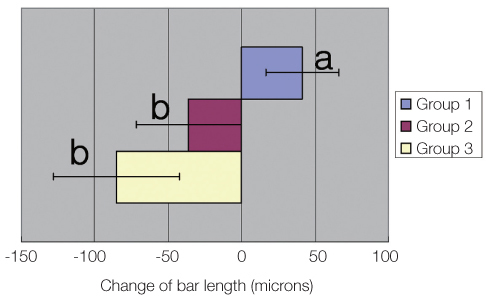

Thirty cast implant bars were fabricated on a metal master model. All cast implant bars were sectioned at 5 mm from the left gold cylinder using a disk of 0.3 mm thickness, and then each group of ten specimens was corrected by gas-air torch soldering, laser welding, and additional casting technique. Three dimensional evaluation including horizontal, vertical, and twisting measurements was based on measurement and comparison of (1) gap distances of the right abutment replica-gold cylinder interface at buccal, distal, lingual side, (2) changes of bar length, and (3) axis angle changes of the right gold cylinders at the step of the post-correction measurements on the three groups with a contact and non-contact coordinate measuring machine. One-way analysis of variance (ANOVA) and paired t-test were performed at the significance level of 5%.

RESULTS

Gap distances of the cast implant bars after correction procedure showed no statistically significant difference among groups. Changes in bar length between pre-casting and post-correction measurement were statistically significance among groups. Axis angle changes of the right gold cylinders were not statistically significance among groups.

CONCLUSION

There was no statistical significance among three techniques in horizontal, vertical and axial errors. But, gas-air torch soldering technique showed the most consistent and accurate trend in the correction of implant bar error. However, Laser welding technique, showed a large mean and standard deviation in vertical and twisting measurement and might be technique-sensitive method.

Keyword

MeSH Terms

Figure

Reference

-

1. Rangert B, Jemt T, Jörneus L. Forces and moments on Brånemark implants. Int J Oral Maxillofac Implants. 1989; 4:241–247.2. Rangert B. Mechanical and biomechanical guidelines for the use of Brånemark System-general principles. Aust Prosthodont J. 1993; 7:39–44.3. Jemt T, Lindén B, Lekholm U. Failures and complications in 127 consecutively placed fixed partial prostheses supported by Brånemark implants: from prosthetic treatment to first annual checkup. Int J Oral Maxillofac Implants. 1992; 7:40–44.4. Hoshaw SJ, Brunski JB, Cochran GVB. Mechanical loading of Brånemark implants affects interfacial bone modeling and remodeling. Int J Oral Maxillofac Implants. 1994; 9:345–360.5. Zarb GA, Symington JM. Osseointegrated dental implants: preliminary report on a replication study. J Prosthet Dent. 1983; 50:271–276.6. Sones AD. Complications with osseointegrated implants. J Prosthet Dent. 1989; 62:581–585.7. Kallus T, Bessing C. Loose gold screws frequently occur in full-arch fixed prostheses supported by osseointegrated implants after 5 years. Int J Oral Maxillofac Implants. 1994; 9:169–178.8. Binon PP. The effect of implant/abutment hexagonal misfit on screw joint stability. Int J Prosthodont. 1996; 9:149–160.9. Pietrabissa R, Gionso L, Quaglini V, Di Martino E, Simion M. An in vitro study on compensation of mismatch of screw versus cement-retained implant supported fixed prostheses. Clin Oral Implants Res. 2000; 11:448–457.10. Jemt T, Lindén B. Fixed implant-supported prostheses with welded titanium frameworks. Int J Periodontics Restorative Dent. 1992; 12:177–184.11. Jemt T, Book K. Prosthesis misfit and marginal bone loss in edentulous implant patients. Int J Oral Maxillofac Implants. 1996; 11:620–625.12. Jemt T, Lekholm U. Measurements of bone and frame-work deformations induced by misfit of implant superstructures. A pilot study in rabbits. Clin Oral Implants Res. 1998; 9:272–280.13. Carr AB, Gerard DA, Larsen PE. The response of bone in primates around unloaded dental implants supporting prostheses with different levels of fit. J Prosthet Dent. 1996; 76:500–509.14. Rubenstein JE, Ma T. Comparison of interface relationships between implant components for laser-welded titanium frameworks and standard cast frameworks. Int J Oral Maxillofac Implants. 1999; 14:491–495.15. Assif D, Marshak B, Schmidt A. Accuracy of implant impression techniques. Int J Oral Maxillofac Implants. 1996; 11:216–222.16. Wee AG, Schneider RL, Aquilino SA, Huff TL, Lindquist TJ, Williamson DL. Evaluation of the accuracy of solid implant casts. J Prosthodont. 1998; 7:161–169.17. Chang TL, Maruyama C, White SN, Son S, Caputo AA. Dimensional accuracy analysis of implant framework castings from 2 casting systems. Int J Oral Maxillofac Implants. 2005; 20:720–725.18. Bidez MW, McLoughlin SW, Chen Y, English CE. Finite element analysis of two-abutment Hader bar designs. Implant Dent. 1993; 2:107–114.19. Romero GG, Engelmeier R, Powers JM, Canterbury AA. Accuracy of three corrective techniques for implant bar fabrication. J Prosthet Dent. 2000; 84:602–607.20. Carr AB, Stewart RB. Full-arch implant framework casting accuracy: preliminary in vitro observation for in vivo testing. J Prosthodont. 1993; 2:2–8.21. Linke BA, Nicholls JI, Faucher RR. Distortion analysis of stone casts made from impression materials. J Prosthet Dent. 1985; 54:794–802.22. Humphries RM, Yaman P, Bloem TJ. The accuracy of implant master casts constructed from transfer impressions. Int J Oral Maxillofac Implants. 1990; 5:331–336.23. Gettleman L, Ryge G. Accuracy of stone, metal and plastic die materials. J Calif Dent Assoc. 1970; 46:28–31.24. Sutherland JK, Hallam RF. Soldering technique for osseointegrated implant prostheses. J Prosthet Dent. 1990; 63:242–244.25. Hobo S, Ichida E, Garcia LT. Osseointergration and Occlusal Rehabilitation. Chicago, IL: Quintessence Publishing Co;1989. p. 176.26. Sellers GC. Direct assembly framework for osseointegrated implant prosthesis. J Prosthet Dent. 1989; 62:662–668.27. Voitik AJ. The Kulzer abutment luting; Kal technique. A direct assembly framework method for osseointegrated implant prostheses. Implant Soc. 1991; 2:11–14.28. Parel SM. Modified casting technique for osseointegrated fixed prosthesis fabrication: a preliminary report. Int J Oral Maxillofac Implants. 1989; 4:33–40.29. Eisenmann E, Mokabberi A, Walter MH, Freesmeyer WB. Improving the fit of implant-supported superstructures using the spark erosion technique. Int J Oral Maxillofac Implants. 2004; 19:810–818.30. Berger JC, Driscoll CF. Rehabilitation of a spark erosion prosthesis: a clinical report. J Prosthodont. 2006; 15:113–116.31. Preston JD, Reisbick MH. Laser fusion of selected dental casting alloys. J Dent Res. 1975; 54:232–238.32. Weiss PA, Munyon RE. Repairs, corrections and additions to non-precious ceramo-metal frameworks (II). Quintessence Dent Technol. 1980; 4:45–58.33. Kwon JY, Kim CH, Lim YJ, Kim MJ. The dimensional change of cast implant bars after laboratory procedure. J Korean Acad Prosthodont. 2007; 45:354–361.34. Zoidis PC, Winkler S, Karellos ND. The effect of soldering, electrowelding, and cast-to procedures on the accuracy of fit of cast implant bars. Implant Dent. 1996; 5:163–168.35. Linehan AD, Windeler AS. Passive fit of implant-retained prosthetic superstructures improved by electric discharge machining. J Prosthodont. 1994; 3:88–95.36. Tan KB, Rubenstein JE, Nicholls JI, Yuodelis RA. Three-dimensional analysis of the casting accuracy of one-piece, osseointegrated implant-retained prostheses. Int J Prosthodont. 1993; 6:346–363.37. Iwasaki K, Ohkawa S, Rosca ID, Uo M, Akasaka T, Watari F. Distortion of laser welded titanium plates. Dent Mater J. 2004; 23:593–599.38. Jemt T. Three-dimensional distortion of gold alloy castings and welded titanium frameworks. Measurements of the precision of fit between completed implant prostheses and the master casts in routine edentulous situations. J Oral Rehabil. 1995; 22:557–564.39. Huling JS, Clark RE. Compratative distortion in three-unit fixed prostheses joined by laser welding, conventioanl soldering, or casting in one piece. J Dent Res. 1977; 56:128–134.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- The dimensional change of cast implant bars after laboratory procedure

- Effect of impression technique on the accuracy of master cast for implant prosthesis

- Effect of impression technique on the accuracy of master cast for implant prosthesis

- Effect of impression coping and implant angulation on the accuracy of implant impressions: an in vitro study

- Erratum: Correction of Figure Legends