Korean J Orthod.

2010 Jun;40(3):156-166. 10.4041/kjod.2010.40.3.156.

Changes in surface roughness of bracket and wire after experimental sliding - preliminary study using an atomic force microscopy

- Affiliations

-

- 1Department of Orthodontics, Kyung-Hee University School of Dentistry, Korea.

- 2Private Practice, Korea.

- 3Department of Biomedical Engineering, Kyung-Hee University School of Medicine, Korea.

- 4Department of Orthodontics, Kyung-Hee University School of Dentistry, Korea. ygpark@khu.ac.kr

- KMID: 1459569

- DOI: http://doi.org/10.4041/kjod.2010.40.3.156

Abstract

OBJECTIVE

The surface roughness of orthodontic materials is an essential factor that determines the coefficient of friction and the effectiveness of tooth movement. The aim of this study is to evaluate the surface roughness change of the brackets and wires after experimental sliding quantitatively.

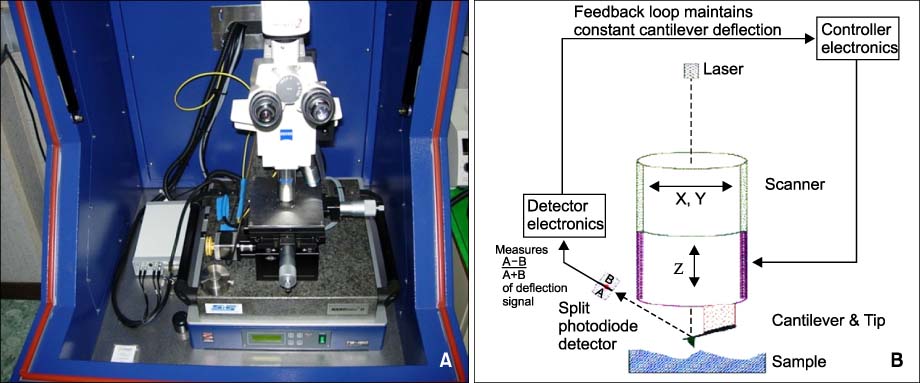

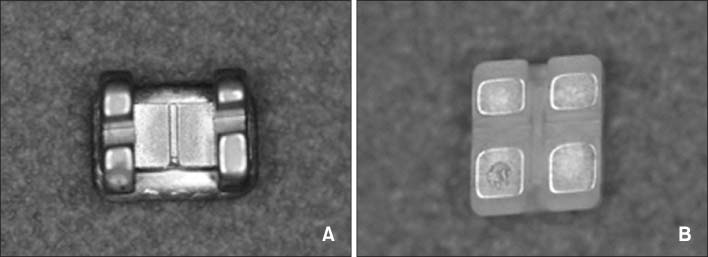

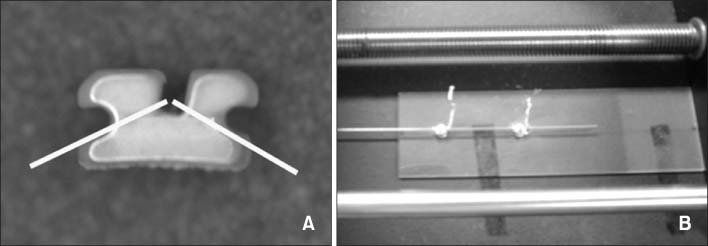

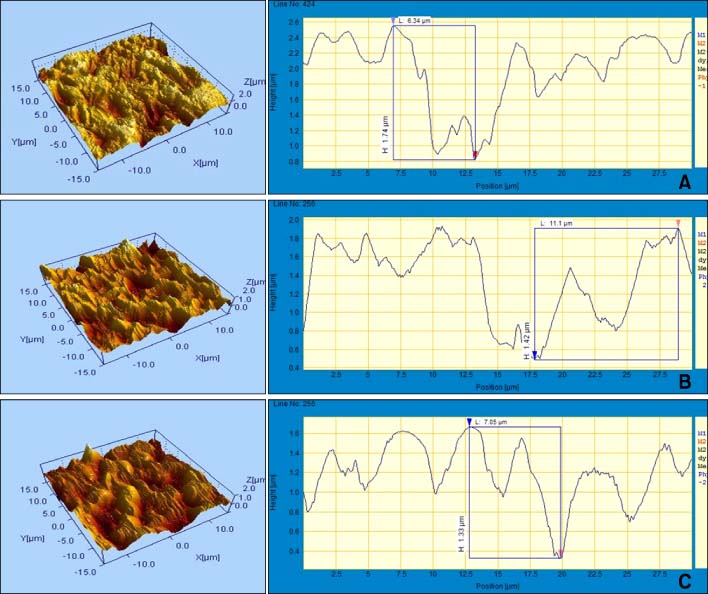

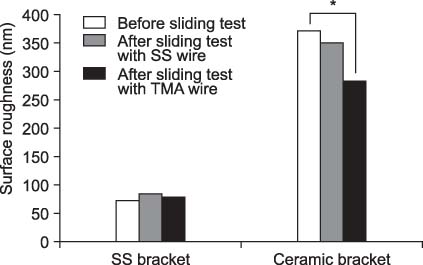

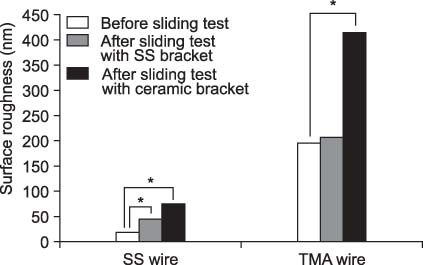

METHODS

Before and after experimental sliding tests, the surface roughness of stainless steel brackets, ceramic brackets, stainless steel wires, and beta-titanium (TMA) wires were investigated and compared using atomic force microscopy (AFM).

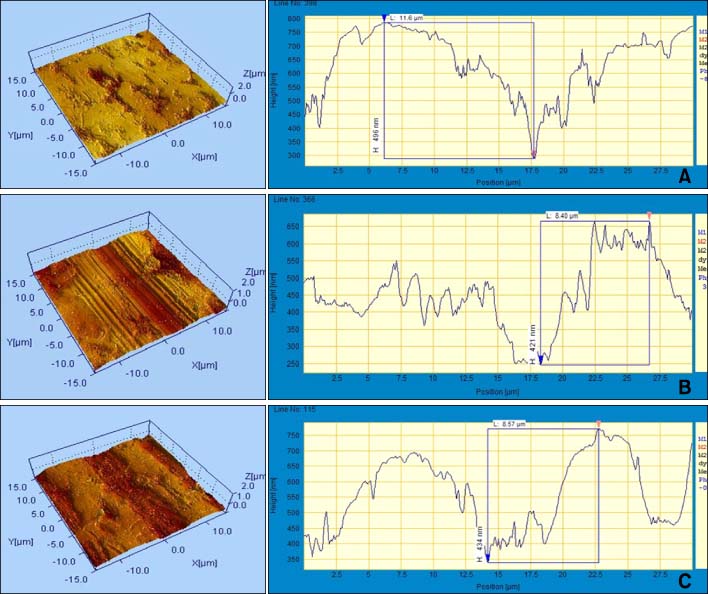

RESULTS

After sliding tests, changes in the surface of the wire were greater than changes in the bracket slot surface. The surface roughness of the stainless steel bracket was not significantly increased after sliding test, whereas the roughness of ceramic brackets was decreased. Both the surface roughness of stainless steel and TMA wires were increased after sliding test. More changes were observed on the ceramic bracket than the stainless steel bracket.

CONCLUSIONS

AFM is a valuable research tool when analyzing the surface roughness of the brackets and wires quantitatively.

Keyword

MeSH Terms

Figure

Reference

-

1. Frank CA, Nikolai RJ. A comparative study of frictional resistances between orthodontic bracket and arch wire. Am J Orthod. 1980. 78:593–609.

Article2. Angolkar PV, Kapila S, Duncanson MG Jr, Nanda RS. Evaluation of friction between ceramic brackets and orthodontic wires of four alloys. Am J Orthod Dentofacial Orthop. 1990. 98:499–506.

Article3. Kapur Wadhwa R, Kwon HK, Sciote JJ, Close JM. Frictional resistance in ceramic and metal brackets. J Clin Orthod. 2004. 38:35–38.4. Kapila S, Angolkar PV, Duncanson MG Jr, Nanda RS. Evaluation of friction between edgewise stainless steel brackets and orthodontic wires of four alloys. Am J Orthod Dentofacial Orthop. 1990. 98:117–126.

Article5. Peterson L, Spencer R, Andreasen G. A comparison of friction resistance for Nitinol and stainless steel wire in edgewise brackets. Quintessence Int Dent Dig. 1982. 13:563–571.6. Stannard JG, Gau JM, Hanna MA. Comparative friction of orthodontic wires under dry and wet conditions. Am J Orthod. 1986. 89:485–491.

Article7. Thorstenson GA, Kusy RP. Comparison of resistance to sliding between different self-ligating brackets with second-order angulation in the dry and saliva states. Am J Orthod Dentofacial Orthop. 2002. 121:472–482.

Article8. Kusy RP, Whitley JQ. Assessment of second-order clearances between orthodontic archwires and bracket slots via the critical contact angle for binding. Angle Orthod. 1999. 69:71–80.9. Sims AP, Waters NE, Birnie DJ, Pethybridge RJ. A comparison of the forces required to produce tooth movement in vitro using two self-ligating brackets and a pre-adjusted bracket employing two types of ligation. Eur J Orthod. 1993. 15:377–385.

Article10. Dowling PA, Jones WB, Lagerstrom L, Sandham JA. An investigation into the behavioural characteristics of orthodontic elastomeric modules. Br J Orthod. 1998. 25:197–202.

Article11. Ireland AJ, Sherriff M, McDonald F. Effect of bracket and wire composition on frictional forces. Eur J Orthod. 1991. 13:322–328.

Article12. Andreasen GF, Quevedo FR. Evaluation of friction forces in the 0.022 × 0.028 edgewise bracket in vitro. J Biomech. 1970. 3:151–160.

Article13. Baker KL, Nieberg LG, Weimer AD, Hanna M. Frictional changes in force values caused by saliva substitution. Am J Orthod Dentofacial Orthop. 1987. 91:316–320.

Article14. Riley JL, Garrett SG, Moon PC. Frictional forces of ligated plastic and metal edgewise brackets. J Dent Res. 1979. 58:A21.15. Bourauel C, Fries T, Drescher D, Plietsch R. Surface roughness of orthodontic wires via atomic force microscopy, laser specular reflectance, and profilometry. Eur J Orthod. 1998. 20:79–92.

Article16. Tanne K, Matsubara S, Hotei Y, Sakuda M, Yoshida M. Frictional forces and surface topography of a new ceramic bracket. Am J Orthod Dentofacial Orthop. 1994. 106:273–278.

Article17. Saunders CR, Kusy RP. Surface topography and frictional characteristics of ceramic brackets. Am J Orthod Dentofacial Orthop. 1994. 106:76–87.

Article18. Pratten DH, Popli K, Germane N, Gunsolley JC. Frictional resistance of ceramic and stainless steel orthodontic brackets. Am J Orthod Dentofacial Orthop. 1990. 98:398–403.

Article19. Zinelis S, Eliades T, Eliades G, Makou M, Silikas N. Comparative assessment of the roughness, hardness, and wear resistance of aesthetic bracket materials. Dent Mater. 2005. 21:890–894.

Article20. Prososki RR, Bagby MD, Erickson LC. Static frictional force and surface roughness of nickel-titanium arch wires. Am J Orthod Dentofacial Orthop. 1991. 100:341–348.

Article21. Kusy RP, Whitley JQ, Mayhew MJ, Buckthal JE. Surface roughness of orthodontic archwires via laser spectroscopy. Angle Orthod. 1988. 58:33–45.22. Horton CB, Paulus HM, Pelleu GB, Rudolph JJ. An evaluation of commercial pastes for finishing composite resin surfaces. J Presthet Dent. 1977. 37:674–679.

Article23. Roulet JF, Roulet-Mehrens TK. The surface roughness of restorative materials and dental tissues after polishing with prophylaxis and polishing pastes. J Periodontol. 1982. 53:257–266.

Article24. Cassinelli C, Morra M. Atomic force microscopy studies of the interaction of a dentin adhesive with tooth hard tissue. J Biomed Mater Res. 1994. 28:1427–1431.

Article25. Marshall GW Jr, Balooch M, Tench RJ, Kinney JH, Marshall SJ. Atomic force microscopy of acid effects on dentin. Dent Mater. 1993. 9:265–268.

Article26. Marshall GW Jr, Balooch M, Kinney JH, Marshall SJ. Atomic force microscopy of conditioning agents on dentin. J Biomed Mater Res. 1995. 29:1381–1387.

Article27. Hansma PK, Elings VB, Marti O, Bracker CE. Scanning tunneling microscopy and atomic microscopy: application to biology and technology. Science. 1988. 242:209–216.

Article28. Blanchard CR. Atomic force microscopy. Chem Educator. 1996. 1:1–8.

Article29. Lal R, John SA. Biological applications of atomic force microscopy. Am J Physiol. 1994. 266:C1–C21.

Article30. Radmacher M, Tillamnn RW, Fritz M, Gaub HE. From molecules to cells: imaging soft samples with the atomic force microscope. Science. 1992. 257:1900–1905.

Article31. Ohnesorge F, Binnig G. True atomic resolution by atomic force microscopy through repulsive and attractive forces. Science. 1993. 260:1451–1456.

Article32. Drake B, Prater CB, Weisenhorn AL, Gould SA, Albrecht TR, Quate CF, et al. Imaging crystals, polymers, and processes in water with the atomic force microscopy. Science. 1989. 243:1586–1589.

Article33. Kim HS, Woo YH. A study on surface roughness of composite resins after finishing and polishing. J Korean Acad Prosthodont. 1997. 35:719–741.34. Park KH. Surface analysis about bracket slots for orthodontics by AFM. [Dissertation]. 2009. Seoul: Kyung Hee University.35. Je YJ, Chang MH, Lim YK, Lee DY. Evaluation of friction of esthetic brackets according to different bracket-wire angulations. Korean J Orthod. 2007. 37:341–350.36. Matasa CG. Graber TM, Vanarsdall RL, editors. Biomaterials in orthodontics. Orthodontics: current principles and techniques. 2000. 3rd ed. St. Louis: Mosby;331–332.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Surface roughness analysis of ceramic bracket slots using atomic force microscope

- Surface analysis of metal clips of ceramic self-ligating brackets

- Frictional forces in the fixed orthodontic appliance during tooth movement

- A comparative study of frictional resistances between orthodontic brackets and arch wire during sliding movement of teeth

- A study on frictional resistance force of orthodontic resin bracket